Control Software

Modern folding machines are only able to achieve maximum performance, flexibility, and speed when software and hardware form a single, seamless unit. Hans Schröder Maschinenbau has not only been a leading manufacturer of high-quality folding machines for decades but also a pioneer in the digital controls for these machines.

Our service: Perfectly matched hardware and software from a single source. Every step of the process is supported continuously, from creation of the program for various products to storing them as bending simulations and operator guidance during serial production.

POS 3000

POS 3000 3D graphic control – Interactive sheet design

With the POS 3000 3D graphic control, Schröder Group is setting new standards in the control of industrial sheet metal processing.

With POS 3000 controls the extensive capabilities offered by the high-end folding machines of the Evolution series can be used efficiently. Hardware and software have been developed as a unit – including control over complex machine options like automatic tool changers and handling robots.

Programming with the POS 3000 is done on a touch screen. Individual product profiles can be designed easily via the intuitive finger-activated drawing feature. The exact dimensions may be entered and changed in the dimensioning menu.

The machine, tool, work piece, and type of bend are all clearly displayed. 3D bending simulator allows the check of a program and provides extra security and highest quality starting from the first work piece.

POS 2000 Professional

POS 2000 Professional – the standard for industrial folding machines

The proven POS 2000 Professional makes programming a folding machine fast and comfortable. The desired program components can be selected from a comprehensive and expandable catalog, the angle and side dimensions are easily changed by pressing the monitor.

The control software displays exactly what the machine is doing: The folding machine, work piece, and tool are displayed schematically and updated for every bending step. Anyone who programs preparation of the work away from the machine can test the quality of their program using the bending simulation, which effectively avoids waste and delays during production.

The software not only controls the machine, but also offers assistance to the user: all of the necessary operator activities like turning, rotating, etc. are displayed for each bending step.

Available for:

PowerBend Industrial

PowerBend Professional

PowerBend Multi

MAKU

Classic Bend

Classic Bend – the most clearly laid-out alphanumeric control

The latest software invention from Schröder Group and perfect for workshop and factory application: Classic Bend is a modern alphanumeric control that serves as the standard software for the folding machines MAKU and PowerBend Universal.

Classic Bend controls the clamping beam and the folding beam using a path measurement system, and the motorized back stop is controlled via the digitally controlled frequency inverter. The user interface is clearly laid-out and combines easy-to-understand icons with text and numerical displays.

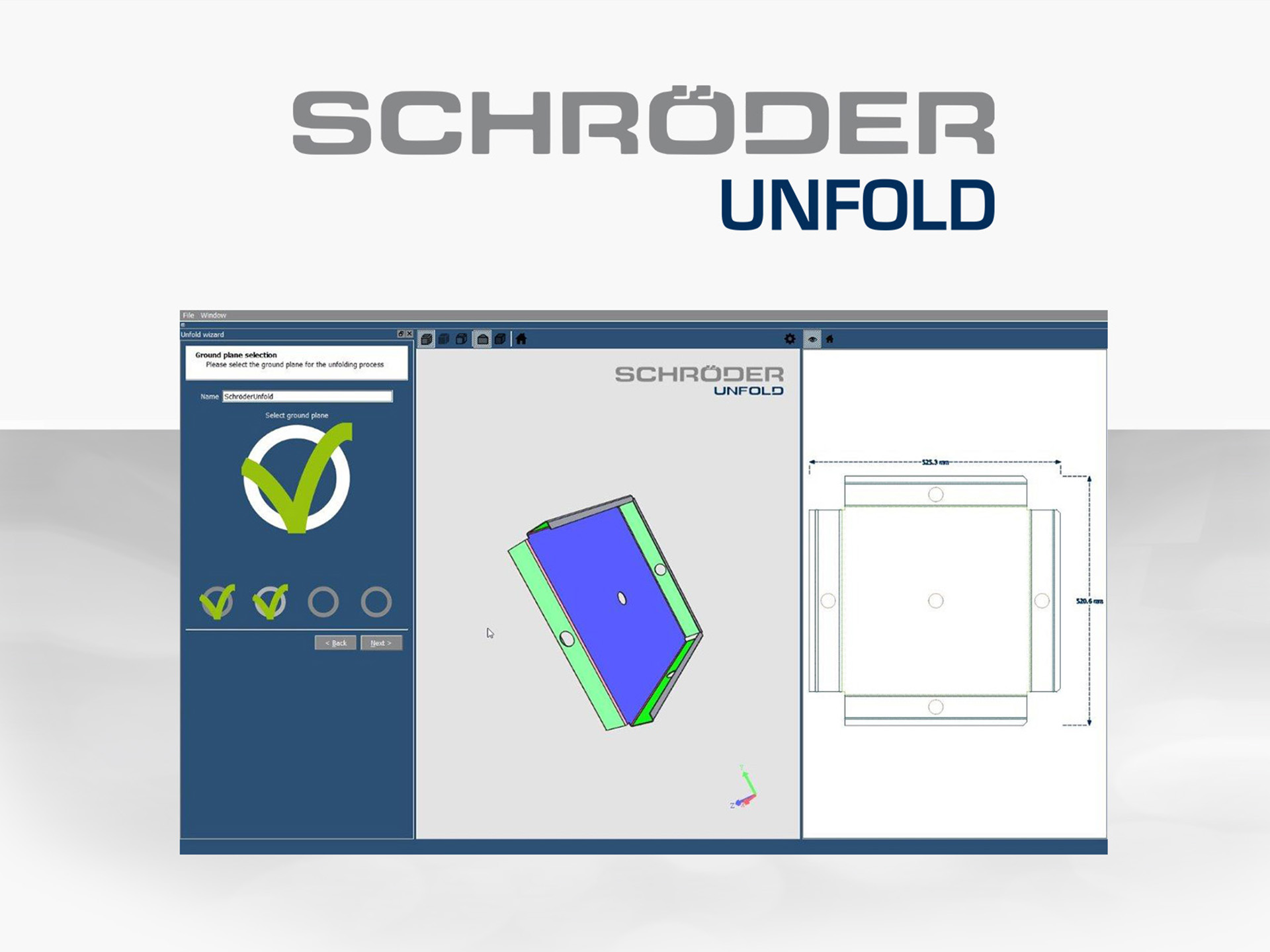

Unfold software - Schröder Unfold

Uncomplicated and simple – the new

unfold software “SCHRÖDER Unfold“

In order to coordinate hardware and software

perfectly, Hans Schröder Maschinenbau developed

an unfold software to calculate the blank size

and program with effortless precision. Step-files

are imported into Schröder unfold, they are

unfolded to create the flat pattern, calculating

cut size, notch development, and internal

geometry placement. The most efficient bending sequence is then calculated and the machine

program created. The last step is the creation of

the flat profile in a DXF format that can be

exported for use in the blank creation process.