Schröder Group at the Dach + Holz International Stuttgart 2024

Innovative machine options

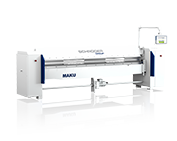

Wessobrunn-Forst (Germany), 25 January 2024 – The Schröder Group will be exhibiting at Dach + Holz International Stuttgart from March 5 to 8, 2024. In addition to classic machines for handicraft, motorized folding machines and shears will also be on display at stand 7.410 in hall 7, which enable roofers and plumbers to effortlessly achieve maximum repeat accuracy for larger series. Conical bending on motorized folding machines, invented by Hans Schröder Maschinenbau, offers a particular simplification. The two motorized folding machines on display, MAKU and PowerBend Multi, are capable of producing high-precision plug-in profiles.

One of the most important exhibition machines at the Schröder booth is the versatile MAKU folding machine for up to 1.5 mm thick sheets over a working length of 3200 mm. The outstanding option of the machine is conical bending. Roofers and plumbers in particular often have to deal with conical bends for parapet or wall coverings, roof edge finishes, verge sheets or claddings that have to have a slope. Until now, anyone who did not have a long folding machine with the appropriate equipment could only do it manually. The Schröder Group solves this problem with an electronically controlled two-axis back gauge, with which conical and form-fit profiles can be produced with a precision in the tenth of a millimeter range.

Folding hems in just one working step

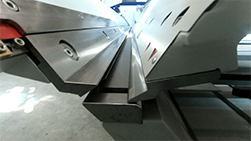

The PowerBend Multi (PBM) is a versatile folding machine for processing up to 2.5 mm thick sheets. At Dach + Holz, this machine will be attracting attention with a patented innovation in addition to the conical stop: in combination with the rotating clamping beam option, it is possible to reset the clamping beam, clamp the sheet and make room for the folding beam in order to fold hems. Instead of the traditional clamping with the clamping beam, the same applies here: What can be bent can also be pressed shut. In the case of the exhibition machine, this means folding hems out of a 2 mm thick steel sheet over a working length of 3200 mm.

Modern classics

Another Schröder Group exhibit at Dach + Holz is the MHSU guided motorized sheet metal shear, the entry-level model for motorized shears. The machine is characterized, among other things, by a 750 mm back gauge with digital display that can be adjusted from the front. The machine on show at the exhibition also has the “Classic Cut” NC positioning gauge. This is used to program different back gauge lengths. This makes handling easier and allows precise positioning of the workpiece. Another option on show is the new, variable sheet metal holding device. Whereas previously a customer had to decide at the time of purchase whether the sheet should be ejected forwards or backwards after cutting, this can now be selected at any time at the touch of a button.

Other machines on the stand include the AK (2000×1.5) and ASK 3 (1250×1.5) folding machines and the 102 (10/1.5) slip bending roll. Interesting options are available for the AK with foot pedal to operate the clamping beam. These include the manual back gauge with digital display, which eliminates the need to mark bending edges, an additional bending angle gauge and a convenient pneumatic bending assistant.

The ASK 3 segment folding machine is the guarantor of flexibility among manual folding machines. In addition to standard features such as the patented eccentric quick clamping on the clamping beam, the latest version of the ASK also offers optional free passage heights of up to 180 mm on the clamping beam, up to 120 mm on the bottom beam and up to 142 mm on the folding beam

.

The small slip bending roll 102 offers maximum round forming accuracy. The top roll with swivel bearing has a fold groove for producing folded tubes, the bottom roll and back roll have wire insert grooves.