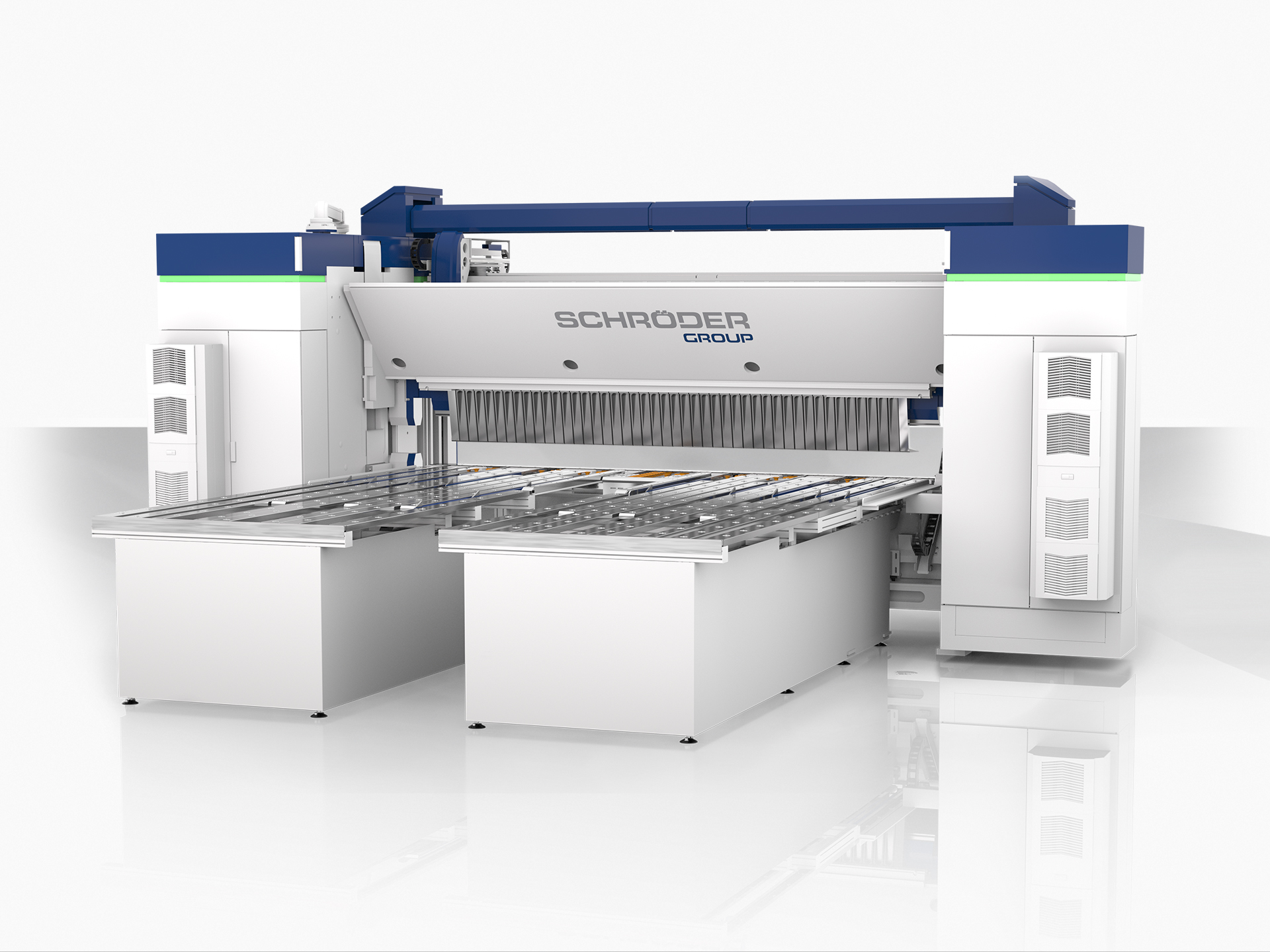

EVO DuoBend

Overview

The new motorized folding machine EVO DuoBend owes its name „DuoBend“ to its two independently operated folding beams. With the EVO DuoBend, the Schröder Group is once again increasing its flexibility in the area of sheet metal folding many times over: Products for container construction, vehicle construction or conventional folding applications, such as heavy sheets with counterbends, can be manufactured efficiently.

Details

- Software control

- POS 3000 3-D Graphic control on swivelling arm

- Radius function

- Remote maintenance via Internet

- External programming (PC-Version 1. Licence)

- Back gauge

- Gauge table 1700 mm as U-shape divided support plates with steel balls

- Lateral angle gauge right and left side 1500 mm (outside)

- Suction plates in gauge table, controlled via POS 3000

- 2 pneumatic pop up square arms assembled aisle side, program-controlled

- Gauge axis in front

- Clamping beam

- Clamping beam stroke: 850 mm

- Clamping beam geometry: 180°

- Fully automatic tool changer WZS 6500: for clamping beam tools with a hydraulic tool clamping device (a total of 8 axis) for max. tool height of 500 mm,

two asynchronously movable tool changers with one gripper unit each

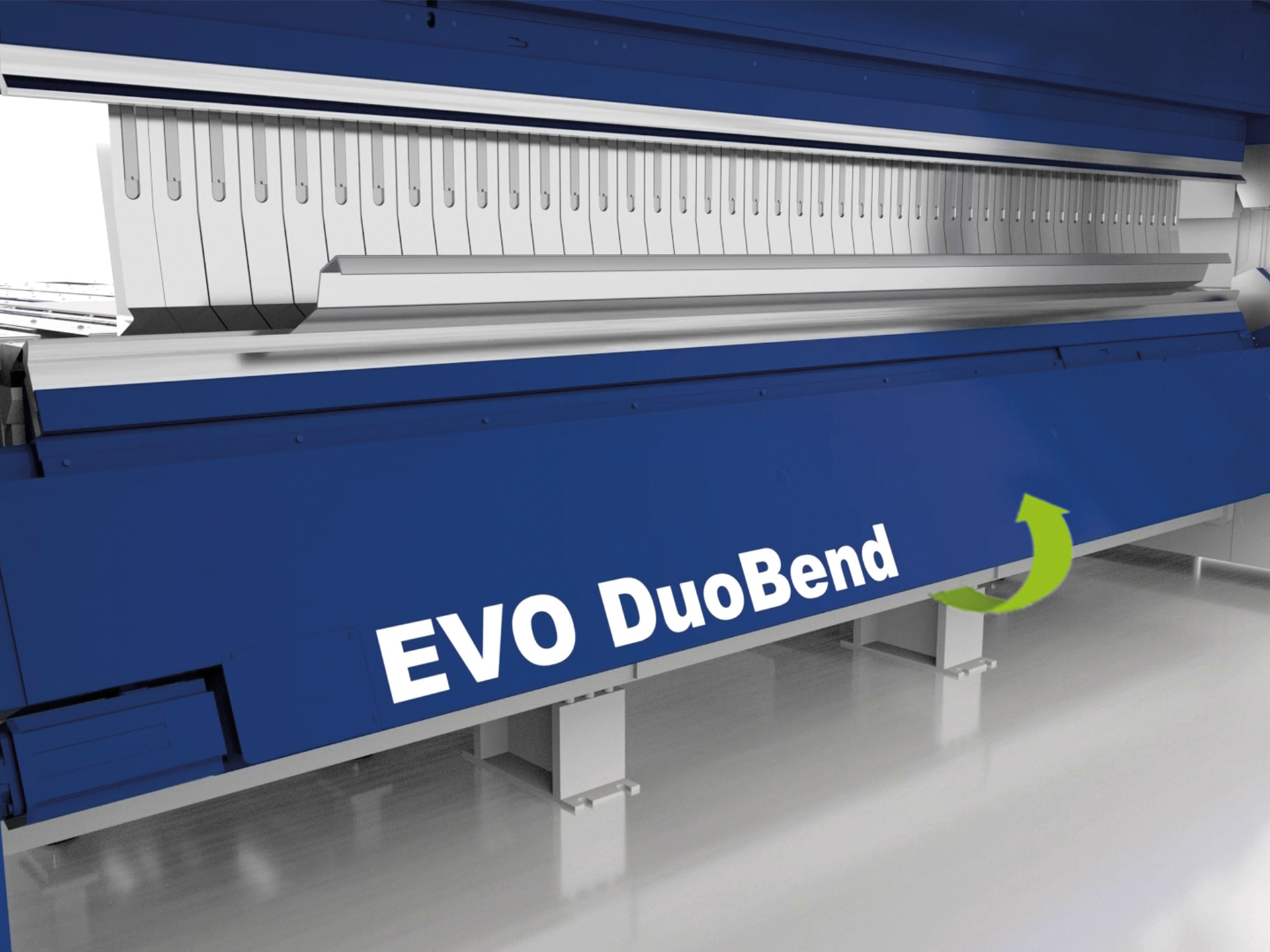

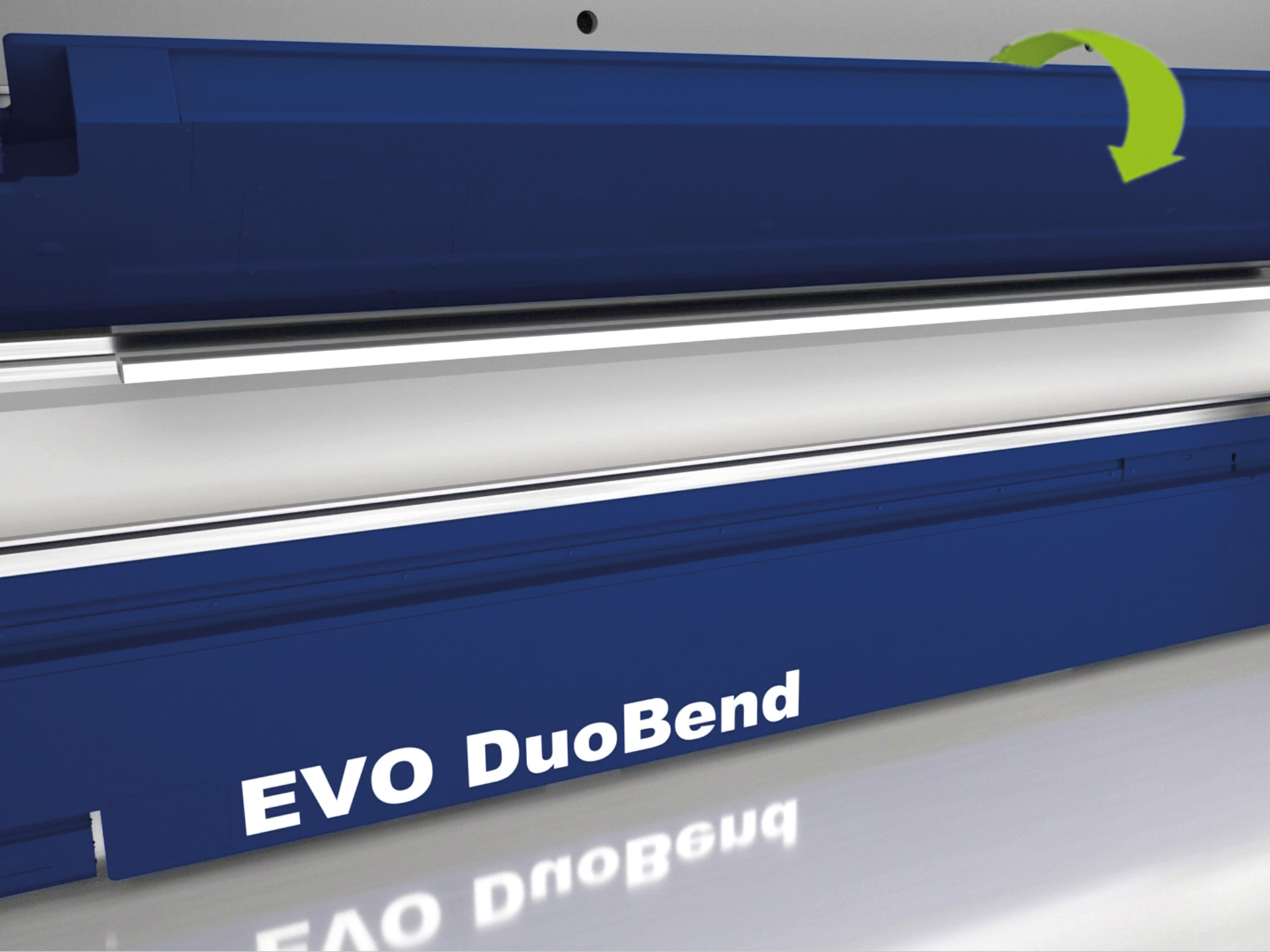

- Folding beam

- Two folding beams, program-controlled

- Mechanic tool clamping device (screwed) (WZS 19000)

- Motorized folding beam adjustment 150 mm

- Motorized folding center adjustment 370 mm

- Motorized central crowning device in both beams

- Work safety

- Protection via light curtain controlled by safety-PLC for operation

from the rear - Safety fence with double doors

- Protection via light curtain controlled by safety-PLC for operation

- Others

- Standard machine without tools

- Working height 1160 mm

- Foot switch, anchor plates incl. dowels, decentralized lubrication system

- Air conditioner on both switch cabinets

Technical data

| Type | Working length | Sheet thickness 400 N/mm2 |

| [mm] | [mm] | |

| 3200×5,0 | 3240 | 5,00 |

| 4000×4,0 | 4040 | 4,00 |

Software

Software

Software

POS 3000 3D graphic control:

Interactive sheet design

POS 3000 3D graphical controls is one of the most powerful controls on the market, and because both the hard- and software come from a single provider, the SPB Evolution UD and POS 3000 3D graphical controls are a perfect match.

Working with POS 3000 is extremely comfortable:

Clearly laid-out product selection including a search function and navigation in submenus enables the operator to select work steps and connect them in the production plan menu to create sequences. Individual product profiles can be designed very quickly via the intuitive finger-activated drawing feature. The exact dimensions may be entered and changed in the dimensioning menu. In order to check and coordinate together with the customer, the drawing may be output on paper using a printer.

Using the program that is created, the software generates the optimal sequence of bends, including automatic collision and threshold value monitoring. The folding angle and cut are corrected automatically using interpolation from the database.

Unfold software – Schröder Unfold

Unfold software – Schröder Unfold

Uncomplicated and simple

In order to coordinate hardware and software perfectly, Hans Schröder Maschinenbau developed an unfold software to calculate the blank size and program with effortless preciscion.

Tools/Options

Special equipment

- Software control

- SCHRÖDER Unfold software

- Back gauge

- Side table left or right, sheet support table closed with ball rollers

- 2 storage tables for manual unloading, can be lowered mechanically, sheet support table with ball rollers

- 2x table flap to close the gap between the stop and side table

- Pneumatically lowerable gauge fingers (2 sectors 850/1700 mm)

- Back gauge extension right and/or left with pneumatically lowerable gauge fingers (balls in table), combinable with side table

- Gripper gauge system: U-shaped table 2000 mm, movement range 150 – 2150 mm, 2 lateral moveable pneumatic grippers

Additional gauge options:

– 2 gauge fingers

– 2 suction plates

(gauge options cannot be used in combination)

2 additional side tables left and right, sheet support table closed with

ball rollers to extend the table up to machine width

- Safety

- Additional equipment for 2-man-operation control in accordance with

accident prevention rules required

- Additional equipment for 2-man-operation control in accordance with

- Others

- Voltage transformer 52 kVA

- Overseas packaging

- Tools

- Various folding beam-, clamping beam-, and bottom beam tools