Stock machines, show room machines and used machines

Model

ID

MHSU - 3200 / 2,0

463 (240675)

Model

MHSU - 3200 / 2,0

ID

463 (240675)

Condition

Stock machine

Colour

light grey / sapphire blue

Contact

Equipment/features

Equipment

- Extended sheet support table

- Milled grooves every 10 mm along the table, parallel to the blades

- All-steel blades double-edged

- Fine adjustment screws for material with less thickness 0.5 mm

- Blade opening 10/85

- Adjustable right and left angle gauge with scale

- Foot switch 1-pedal with protective cover

- Anchor plates incl. dowels

- Obligatory CE safety package

Accessories

- NC – Positioning gauge Classic Cut

Sheet support, pneumatically controlled, material to the front, incl. sheet shute

rear guarding via cover - LED cutting edge illumination

- Pneumatic hold-down device

PDC-NC - 3200 / 3,0

467 (241898)

Model

PDC-NC - 3200 / 3,0

ID

467 (241898)

Condition

stock machine

Colour

light grey / sapphire blue

Contact

Equipment/features

Standard equipment

- NC positioning gauge Cut Control, gauge length 6 – 750 mm

- Bilateral drive

- Pneumatially controlled sheet support with sheet separator (material to the front), max. 750 mm

- All-steel blade, double-edged

- Obligatory CE safety package: rear guarding via 2-beam light barrier incl. side protection grid

- Foot switch

- Anchor plates incl. dowels

Optional equipment:

- Closed table

- Support plate with steel balls

- Linear guide at the front for movable table support arms

- Extended angle gauge 1000 mm (right) with scale incl. lateral flip gauge on linear guide

- Motorized blade gap adjustment

- Cutting edge illumination LED

- Pneumatic hold-down device

PDC-NC - 3200 / 3,0

468 (244990)

Model

PDC-NC - 3200 / 3,0

ID

468 (244990)

Condition

stock machine

Colour

light grey / sapphire blue

Contact

Equipment/features

Standard equipment

- NC positioning gauge Classic Cut, Touch-control on turnable panel, gauge length 6-750 mm

- Bilateral drives

- Sheet support, pneumatically controlled to the back, gauge length up to 1000 mm, sheet support table width max. 750 mm

- Pneumatcally controlled sheet support to the front with sheet shute max. 750 mm

- Obligatory CE safety package: rear guarding via 3-beam light barrier incl. side protection grid

- Foot switch

Optional equipment

- Blades designed for stainless steel instead of standard blades

- Back gauge 750 mm with ball screws

- Extended angle gauge right with electron. length measurement system, fine adjustment and lateral flip gauge on linear guide 1000 mm

- Closed table

- Sheet support table with steel balls

- Linear guide at the front for movable table support arms

- 2 movable support amrs for linear guide incl. T-slot and scale 1000 mm

- Motorized blade gap adjustment

- Cutting edge illumination LED

- Pneumatic hold-down device

BAM-10/0.8

268 (242125)

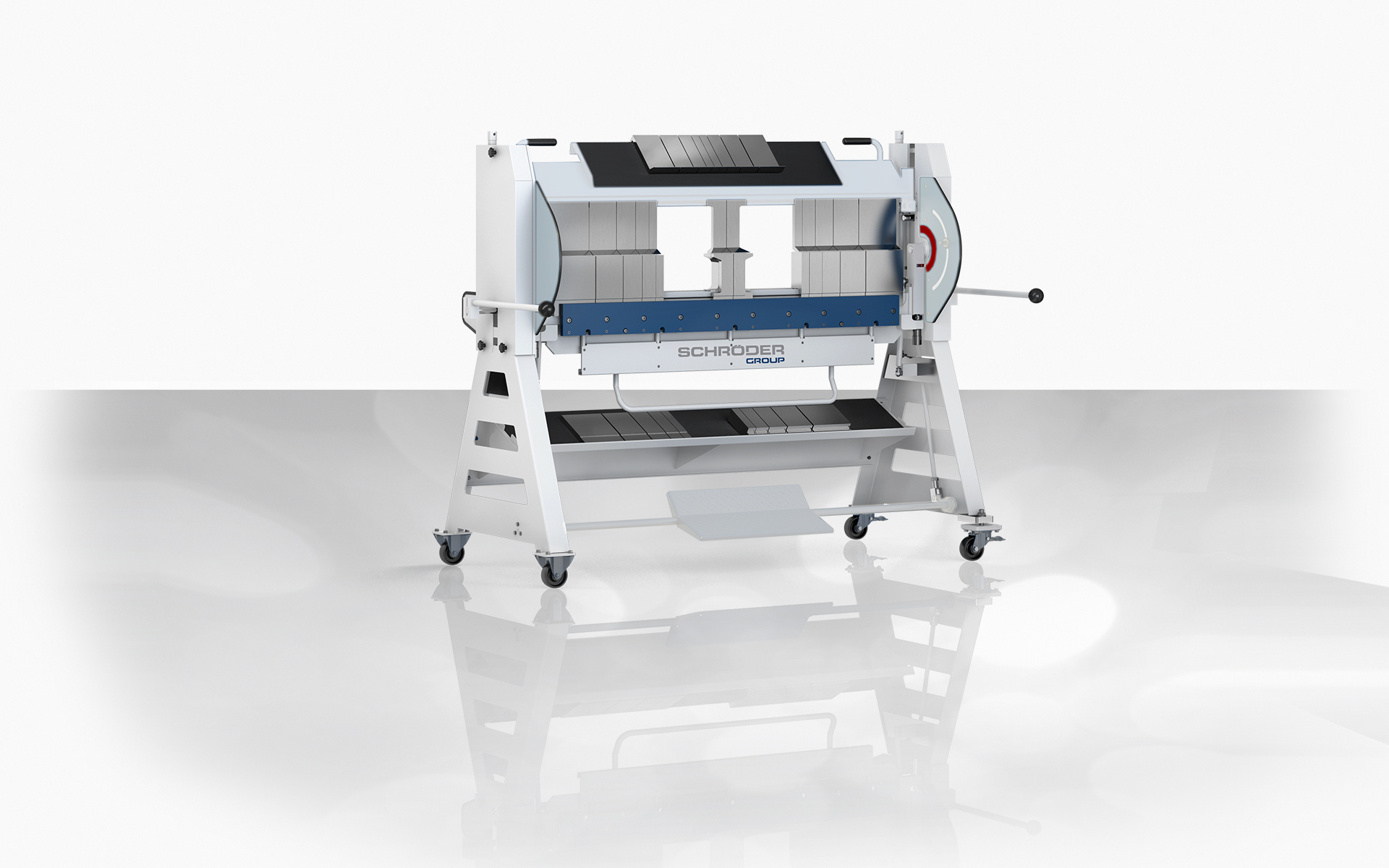

Model

BAM-10/0.8

ID

268 (242125)

Condition

Stock machine

Colour

light grey

Contact

Equipment/features

Equipment

- Quick rotating clamping beam with sharp blade and goat’s foot blade for narrow bendings

- Folding blade 15 mm

- Easy to disassemble and transport

- Quick clamping beam

- Sheet support and back gauge system 500 mm

- Cutting device incl. guide rail for max. sheet thickness 0.8 mm 1.0037

- Stand with 4 castors: 2 fixed and 2 steering castors, lockable

- Bending angle indicator right

BAM-20/0.75

270

Model

BAM-20/0.75

ID

270

Condition

Stock machine

Colour

light grey

Contact

Equipment/features

Equipment

- Sharp-nose blade 20°, exchangeable

- Folding blade 15 mm, exchangeable

- Folding beam with crowning device

- Folding beam adjustment for radius blades

- Clamping beam with counterbalance adjustment

- Quick clamping beam with one-hand operation

- Back gauge and sheet support system 750 mm

- Cutting device incl. guide rail für max. sheet thickness 0.8 mm 1.0037 (S235JR, St37)

- Removable stand with 4 castors: 2 fixed- 2 steering castors, lockable

- Bending angle indicator

ASK3 -1000 / 1,5

261 (236850)

Model

ASK3 -1000 / 1,5

ID

261 (236850)

Condition

Stock machine

Colour

light grey / sapphire blue

Contact

Equipment/features

Equipment

- Patentented quick clamping device for quck change of clamping and folding beam tools

- Multi-stage clamping beam drive for four different tool heights

- Combi-folding blade, 120 x 12/15 mm, free space 77 mm segmented incl. corner parts

- Bottom beam blade, free space 55 mm, segmented incl. corner parts

- Segmentation of tools: 2x 75 mm (corner parts) 30/50/70/100/150/200/300 mm

- Clamping beam with tool storage function

- Stand with depositing plate incl. tool storage function

- Adjustable angle gauge and bending angle indicator

- Foot pedal for opening and closing of clamping beam

- Machine with 4 castors: 2 fixed and 2 steering castors

Accessories:

- 2 variable gauge arms 600 mm with scale, movable on linear guide incl. 2 tipping gauges

- Add. price for folding- and bottom beam blade surface-hardened (recommended for stainless steel applications)

720 - 3200 / 2,0

258 (105102)

Model

720 - 3200 / 2,0

ID

258 (105102)

Condition

Used machine

Colour

light grey / sapphire blue

Contact

Equipment/features

- Fastrak with hydraulic drive

- Software control CFP 120 on swivelling arm, 12″ colour LCD-touchscreen display

- Crowning device automatic

- MAV 72 1 axis motorized drive in front, adjustment range 6 – 200 mm

- Sheet support table at the bottom beam with steel balls

- Goat’s foot tool h = 120 mm