PDC-NC

Overview

The motorized guillotine model PDC-NC is based on the PDC. It features an adjustable blade gap adjustment, extensive standard equipment and an attractive design that all together lead to a significant upgrade compared to the PDC. What you get here is top technology and top design that fully meet your high demands.

Now new:

- New NC-positioning control Classic Cut: entry via touch display

- incremental production queue

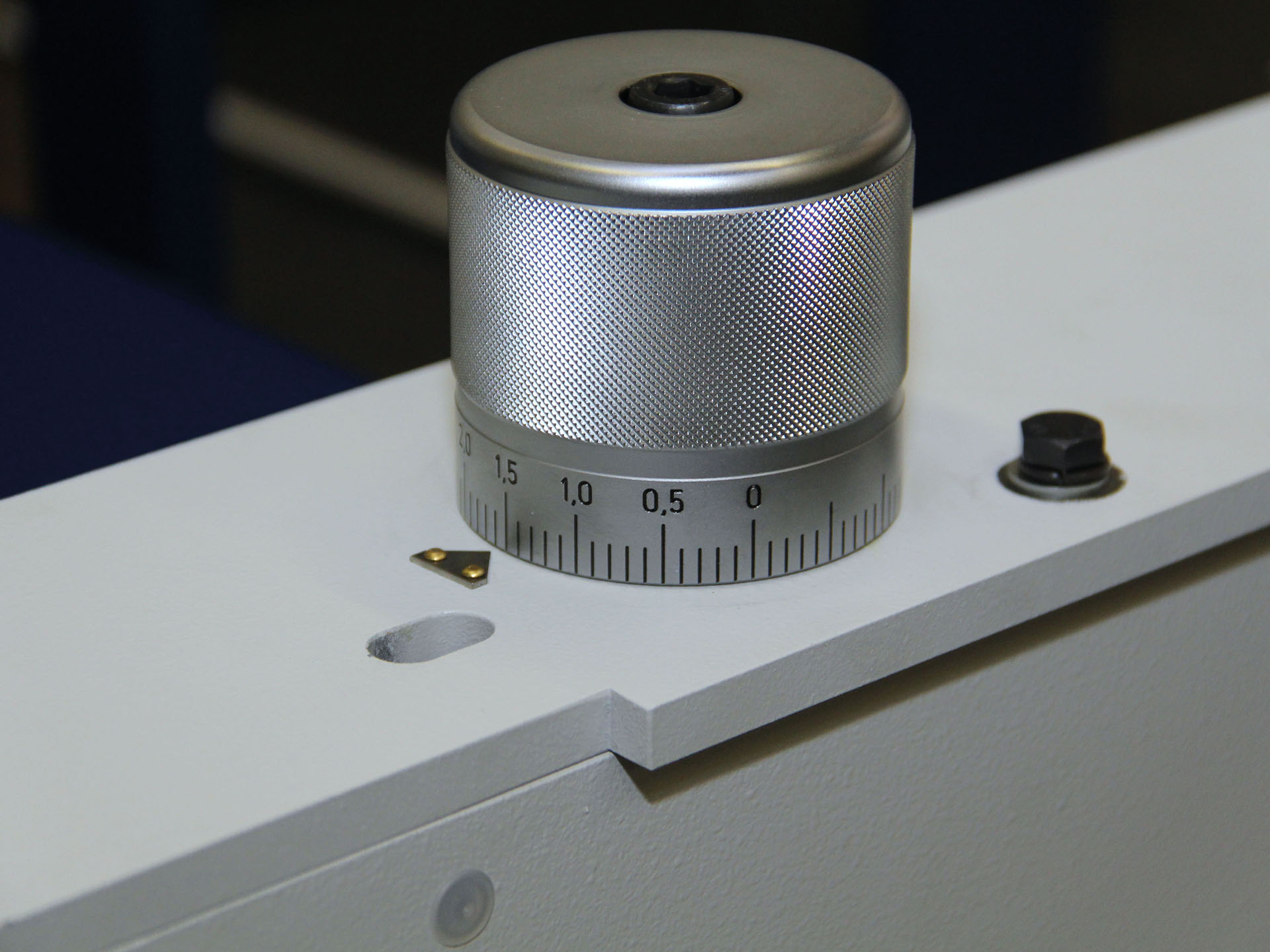

- motorized blade gap adjustment

- motorized back gauge 6 – 750 mm with servo drive

Details

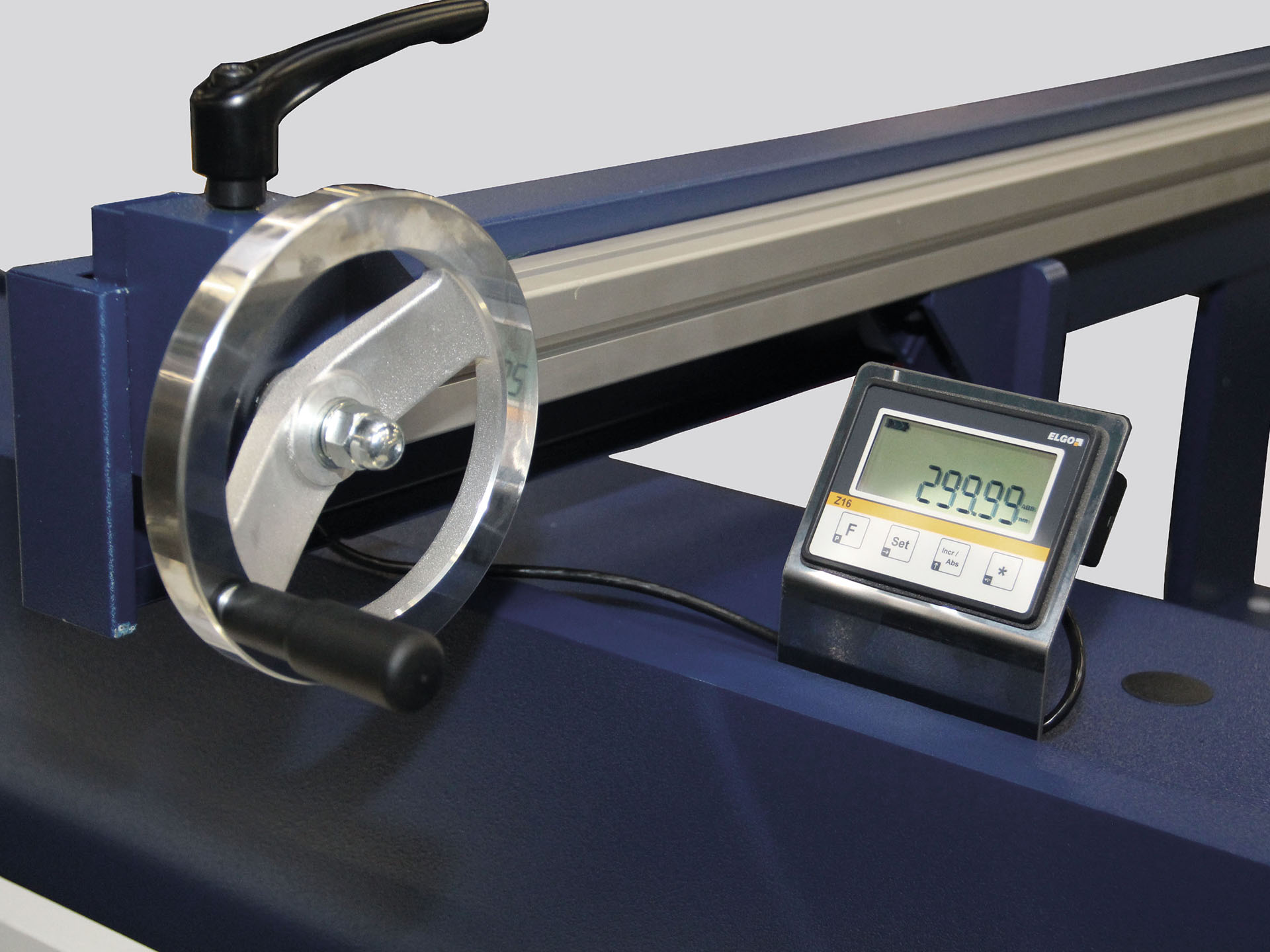

- NC-Positioning control Classic Cut, entry via touchdisplay, motorized back gauge 6 – 750 mm with servo drive

- Cut counter

- Hold-down device with hard rubber rail to protect polished sheets

- Manual blade gap adjustment, two sides

- Extended angle gauge, right, with T-slot and scale 1,000 mm

- All-steel blade, double-edged

- 2 sheet supports with T-slot and scale 1,000 mm

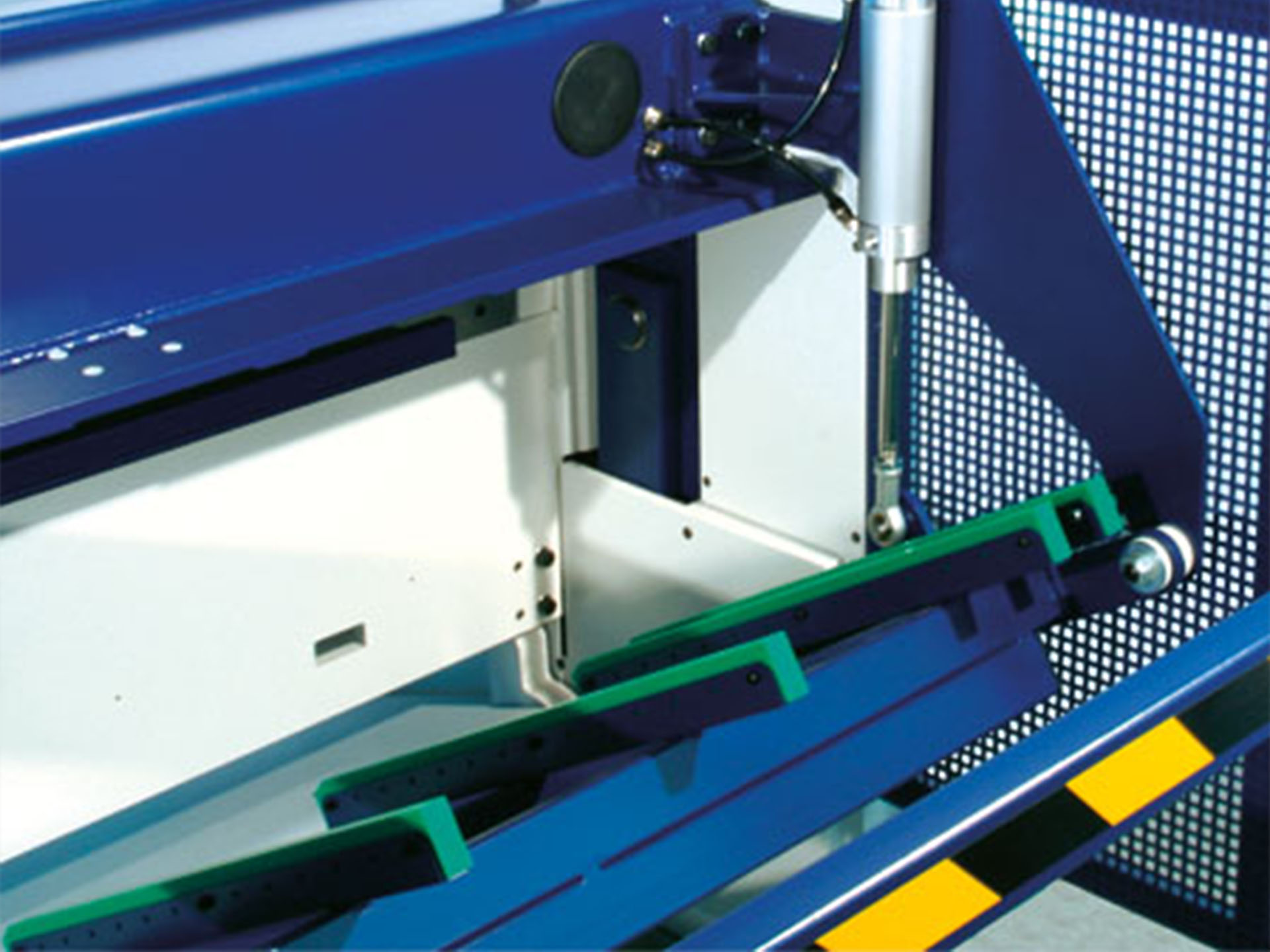

(3 supports arms with a working length of 4000 mm) - Pneumatically controlled sheet support with sheet separator (material to the front), max. 750 mm

optionally:

material to the back, without sheet separator - Table with exchangeable stainless steel plates with recessed grips

- Bilateral drives

- Footswitch

- Anchor plates incl. dowels

- Obligatory safety package

Technical Data

| type | capacity | working length | cutting angle | number of strokes | drive power |

| [mm] | [mm] | [°] | [pro min.] | [kW] | |

| 3200×3,0 | 3,00 | 3230 | 1,6 | 34 | 2×4,0 |

| 4000×2,5 | 2,50 | 4080 | 1,3 | 34 | 2×4,0 |

Options

Options

- Blades designed for stainless steel, instead of standard blades

- Manual back gauge 1000 mm, adjustable from the front with digital readout

- NC-positioning gauge Classic Cut 750 mm or 1000 mm

- Gauge extension up to 1000 mm

- Longlife bearing system

- Back gauge with ball screw spindles

- Sheet support, pneumatically controlled (material to the front) incl. sheet shute 750 mm

- Sheet support, pneumatically controlled (material to the front) for gauge extension max. 1000 mm

- Sheet support, pneumatically controlled (material to the back) sheet support table width max. 750 mm

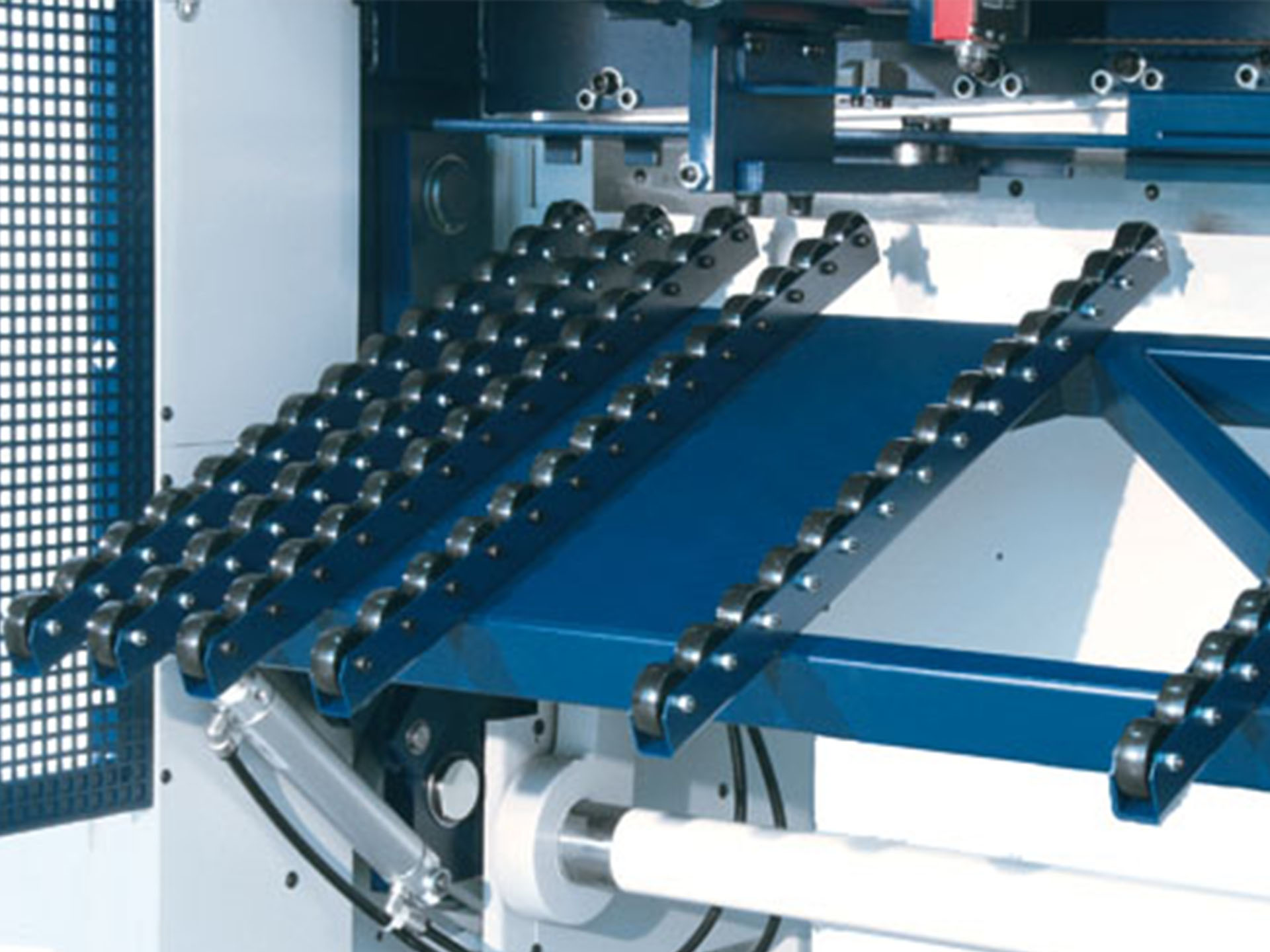

- Closed table, support plate and support arms with ball rollers

- Sheet support arm for closed table with ball rollers, T-slot and scale

- Extended angle gauge (right or left) with T-slot and scale

- Tipping gauge for insertion in T-slot

- Extended angle gauge (right or left) with scale incl. lateral flip gauge on linear guide

- Extended angle gauge (right or left) with electronic lenght measurement system, fine adjustment and lateral flip gauge on linear guide

- Adjustable angle guage with scale division 0 – 180°

- Linear guide at the front for movable table support arms (without support arms)

- Movable support arm for linear guide, at the front, incl. T-slot and scale

- Motorized blade gap adjustment (only in combination with positioning gauge Classic Cut)

- LED cutting edge illumination

- Pneumatic hold-down device

- Stroke counter

- Sheet stacking cart, for back

- Sheet stacking cart, for front (only in combination with working height 950 mm and shortened sheet shute)

- Working height 950 mm

- Shortened sheet shute