Schröder Group presents folding machine EVO DuoBend

More efficient folding with two folding beams

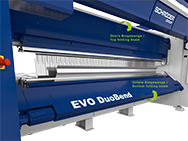

Wessobrunn-Forst (Germany), 7 November 2023 – With the EVO DuoBend, the Schröder Group is once again increasing the flexibility of its up-and-down technology many times over: The new folding machine for up to 5 mm thick sheets has two independently operating folding beams. This opens up completely new possibilities for manufacturing large-format products with opposing bends. In special applications, the simplified handling results in enormous time savings and increased efficiency: Large trapezoidal sheets can be produced with two folding beams in one tenth of the time required with a single up-and-down folding beam. EVO DuoBend will be presented at booth 1805 in hall 1 at Blechexpo 2023.

Large-format sheet metal products with opposing bends, such as those used in container construction, for wind turbines or in special machine construction, are still often manufactured on press brakes with a high level of labor-intensive work. The folding beam of a folding machine with up-and-down function bends the product upward and downward with the swiveling folding beam. These machines have the advantage that sheets, once gauged, do not have to be turned, so that production can be handled by one machine operator alone. With the innovative EVO DuoBend, Schröder extends this principle: The folding of a negative bend is performed by the top folding beam and the folding of a positive bend is performed by the bottom folding beam. This eliminates the need to bypass product sides that have already been bent, which means that there are no longer any restrictions due to the maximum bypass radius of less than 200 mm. The prime example of such workpieces is a customized trapezoidal sheet.

Robust and precise

The EVO DuoBend is available in the working length 4040 mm and 3200 mm. As standard, this machine is equipped with a fully automatic tool changer on the clamping beam, which can be equipped with up to 500 mm high tools. The machine is programmed with Schröder’s own POS 3000 control system, which is already being used successfully on other Schröder folding machines. It calculates the bending program, sets up the tool and finally produces the desired part. The EVO DuoBend offers the flexibility to be used for large production series with high repeatability or for small series and complex parts.

“Already the up-and-down folding beam was perceived as a blessing by cus-tomers handling large sheets. The new EVO DuoBend, with its two folding beams, is another milestone in the triumph of folding technologies. The new ma-chine offers a spectacular minimization of process times for those for whom the limit when going around the bent side of the sheet – 190 millimeters on the MAK Evolution, for example – previously represented a restriction,” says Thomas Os-termair, Head of Sales at Hans Schröder Maschinenbau GmbH.

With the EVO DuoBend Hans Schröder Maschinenbau GmbH is nominated for the innovation award “BlechExpo best-Award 2023“.