MAK 4

Overview

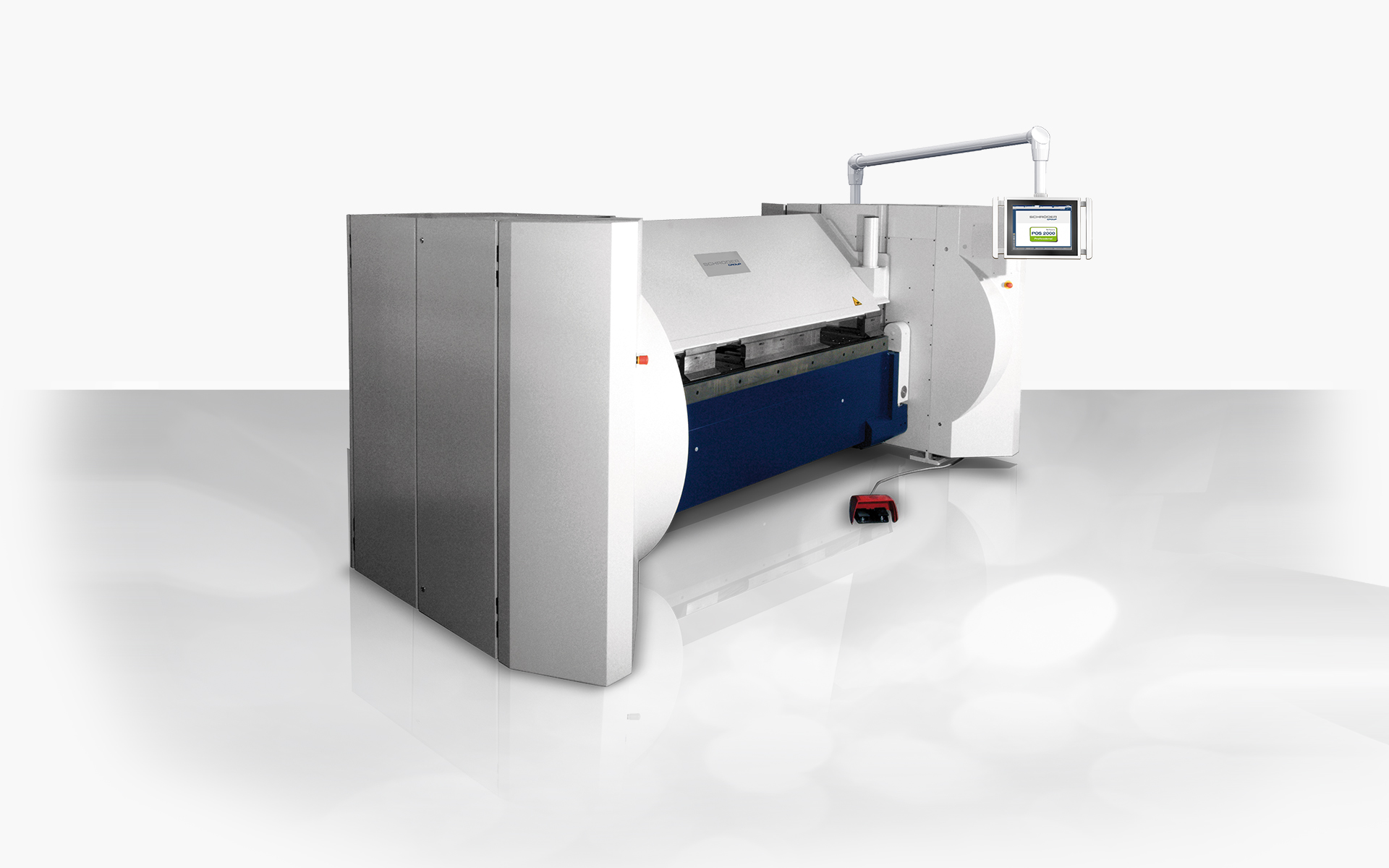

The motorized folding machine MAK 4 can be described as the most powerful and precise folding machine amongst all Schröder Power Folders. With a maximal working length of 5000 mm and a maximum bending capacity of 8 mm, the “giant” is designed for a hard and double shift day.

Details

- Graphic control POS 2000 Professional on swivellng arm

- Sharp-nose blade 30°, R 1.5

- Folding blade 42 mm, divided

- Bottom beam blade, one-piece

- Tools with material strength 1,100 N/mm²

- Folding beam drive, bilateral

- Clamping beam with recirculated ball screws

- POS 2000 Professional control with positioning gauge 10 – 1,000 mm incl. sheet support table

- Hydraulic tool clamping device for clamping beam

- Clamping beam opening 400 mm

- Central crowning device, manual

- Motorized folding beam adjustment, program-controlled

- Piece counter

- Tool set

- Footswitch

- Anchor plates

Technical Data

| type | capacity | working length | clamping beam stroke |

| [mm] | [mm] | [mm] | |

| 3200×6,0 | 6,00 | 3220 | 400 |

| 4000×5,0 | 5,00 | 4020 | 400 |

| type | folding beam adjustment |

bottom beam adjustment |

drive power clamping beam |

drive power folding beam |

| [mm] | [mm] | [kW] | [kW] | |

| 3200×6,0 | 80 | 80 | 2 x 3,0 | 2 x 4,0 |

| 4000×5,0 | 80 | 80 | 2 x 3,0 | 2 x 4,0 |

Software

POS 2000 Professional

the standard for industrial folding machines

The proven POS 2000 Professional makes programming a folding machine fast

and comfortable. The desired program components can be selected from a

comprehensive and expandable catalog, the angle and side dimensions are easily

changed by pressing the monitor.

The control software displays exactly what the machine is doing: The

folding machine, work piece, and tool are displayed schematically and updated

for every bending step. Anyone who programs preparation of the work away from the

machine can test the quality of their program using the bending simulation,

which effectively avoids waste and delays during production.

The software not only controls the machine, but also offers assistance to the user:

all of the necessary operator activities like turning, rotating, etc. are

displayed for each bending step.

Werkzeuge/Optionen

Special equipment

- Crowning device for folding beam – central adjustment, motorized

- Motorized bottom beam adjustment, program-controlled

- Table and back gauge

- sheet support table with balls 10 – 1000 mm

- POS 2000 Professional, gauge 10 – 1500 mm

- Back gauge extension to J- or U-gauge. Base: POS 2000 Professional, gauge 10 – 1000 mm

- 2 pneumatic pop up square arms assembled aisle side, program controlled

Tools

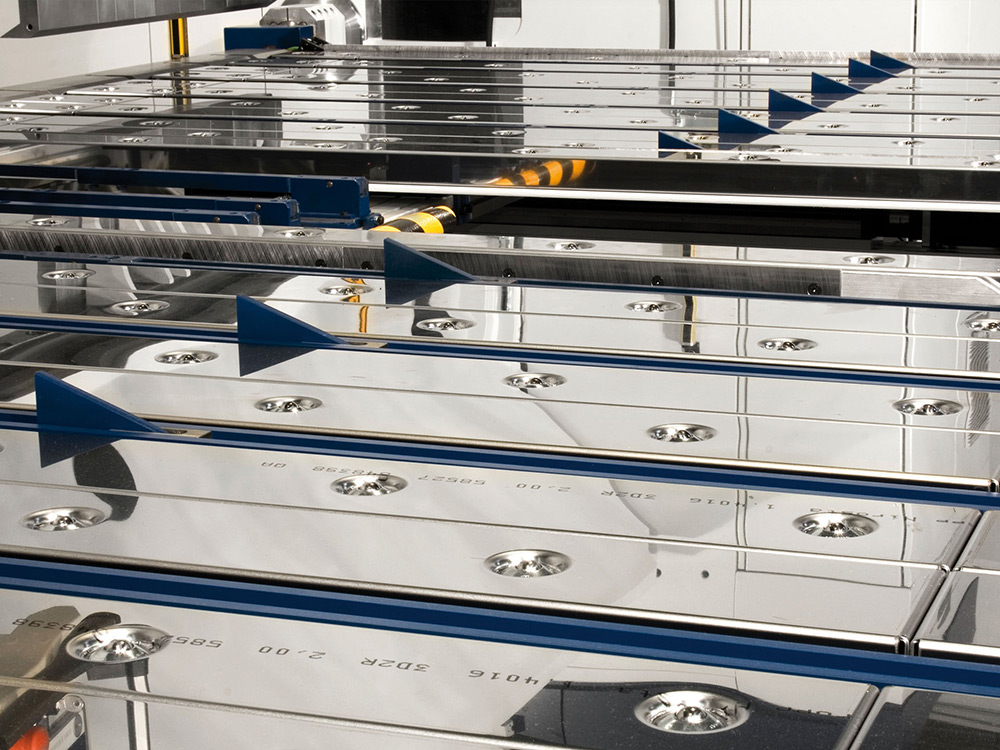

- Bottom beam tools

- Bottom beam blade, clearance 30 mm, segmented, hardened, ca. 1100 N/mm²

- Folding beam tools

- Folding blade segmented, 10/15/20/30 mm, 91 mm high, ca. 1100 N/mm²

- Clamping beam tools with hydraulic tool clamping

- Sharp-nose blade 30°, R 1/1,5/3, divided

- Goat’s foot blade 30°, 120 mm or 170 mm high, R 1/1,5/3, clearance 45 mm, foot width 85 mm