The vivid metal factory

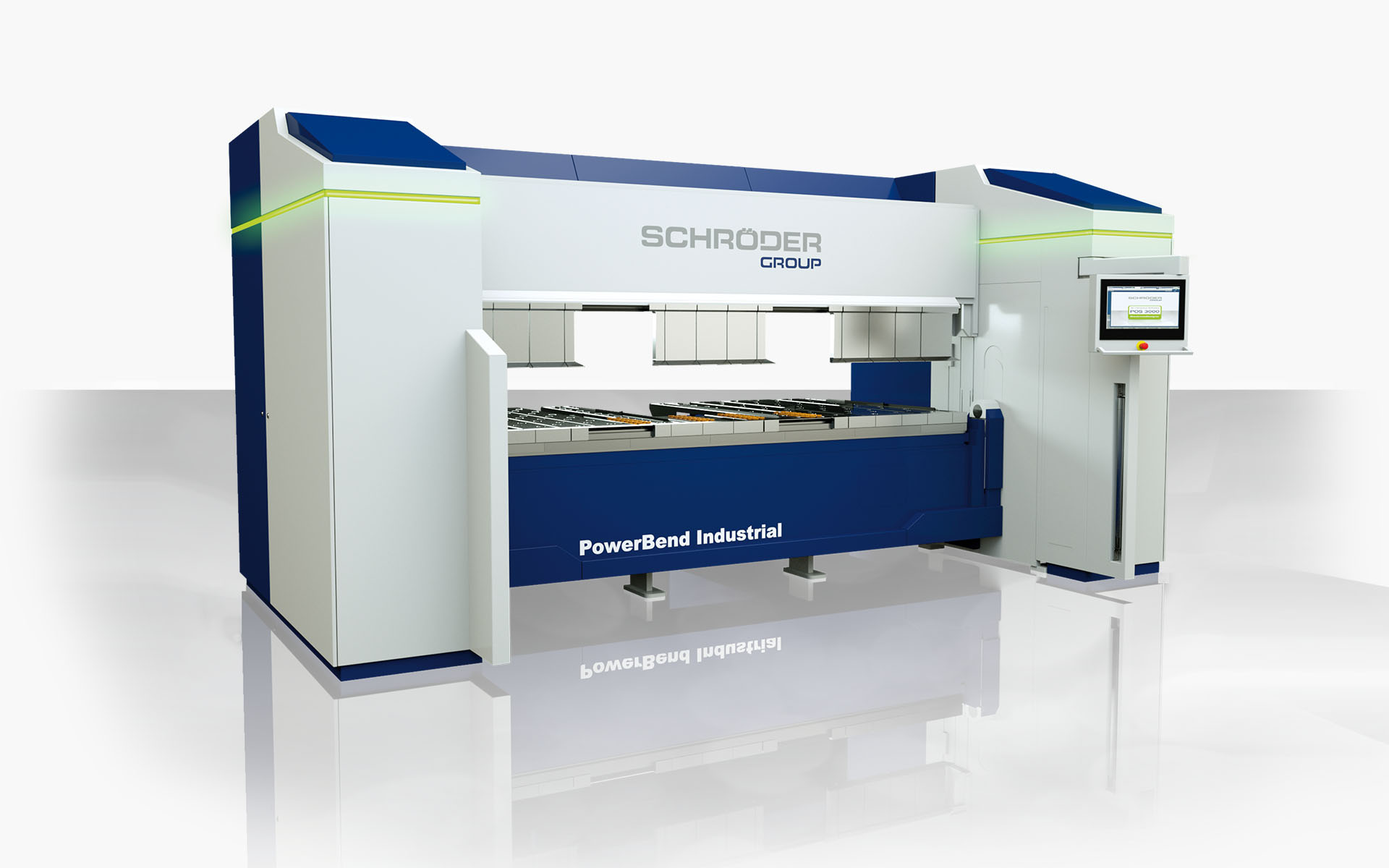

Famous supplier invests in folding machine PowerBend Industrial.

Customer

The MVK GmbH & Co. KG Blech- and Metallverarbeitung is headquartered in Heek close to the German-Dutch border next to Enschede and serves customers from different industries: airplane construction and ship building, wind turbines, agricultural technology, shop fitting and laboratory equipment as well as mechanical engineering and automotive engineering. About 25 000 tons of metal are moved in these production halls a year – in three shifts on six days a week. From more than 100 employees there are more than 25 employed in planning, organisation and administration (www.mvk-metall.de).

Success

A very important criterion for investments at MVK is fl exibility. Staff and machinery support this fl exibility. Flexibility was also the reason for an investment in the folding machine PowerBend Industrial from Schröder. MVK was specifi cally looking for a technological alternative to the existing press brakes. „We were looking for a solution that is more gentle to the surface and that signifi cantly facilitates the handling of bigger sheet metal. Especially with big and thick sheets it gets challenging for manufacturers of folding machines – Schröder is defi nitely a technology leader here“, states the manager of MVK.

Terdenge was visiting an exhibition when he first saw the PowerBend Industrial – and he was convinced at first sight. In order to be able to use the machine for differents tasks, he chose the machine with a working length of 3200 mm, sheet thickness 6 mm and 650 mm clamping beam stroke. Thanks to the Up-and-Downfolding technique and suction cups sheets can be fold automatically in both directions without having to be turned over manually. Hence there is only one operator necessary to process big sheet metal profiles – for MVK this was a great

advantage of the folding machine technique. The second advantage is the gentle treatment of surfaces on the working table and during the folding process. In addition the 3D software control POS 3000 developed inhouse by Schröder is very easy and comfortable to program. „A real benefit is also the fact that the machine can be operated from two sides – in particular small sheets can be processed very fast and comfortably from the rear side of the machine. Therefore there is a second monitor available for operation“, explains Terdenge the advantages.

Radius bending made easy

With the new folding machine MVK extends its machinery and its possibilities further – also regarding its inital planning. The team from MVK is meanwhile also using the radius-step-bending function. With minimum steps and bendings the machine is able to fold precise radii. This means there is no other machine necessary for radius bendings. That facilitates production processes and increases flexiblity.

„The PowerBend Industrial is meanwhile a very important machine for us which creates new opportunities, products and customers thanks to its flexibility and the surface-gentle folding technique. At the same time we and with that also our customers profit thanks to reduced costs as there is only one operator necessary, even with big and heavy sheets“, concludes Terdenge.

„We did not want to expose our company to a price competition. We therefore specialized in small series productions that require a certain production depth with several working steps and that face one or another technical challenges. We organise our production order-based, we achieve high quality and productivity. In addition we invest time in production-related process optimization instead of trying to cram products into existing processes. In many cases we are able to offer our customers the second small series to a more reasonable price as we share our

efficiency gains from process optimization with customers, explains manager Ralf Terdenge. The result is a vivid factory in which the company MVK and its team establish production cells and own processes for each order. In those large-scale halls there is an extremely extensive and versatile machine park: a number of installations for laser cutting, folding machines and slip bending rolls, CNC milling machines and CNC lathes, profile bending machines, welding- and grinding machines. These include rare specialities such as two coupled press brakes, that are

able to bend sheet metal up to 12 400 mm width and 12 cm sheet thickness.

Machine in operation

PowerBend Industrial

- Folding machine up to 6 mm sheet thickness (400 N/mm²)

- 3 200 mm Working length

- Up-and-Down-folding beam

- Suction plates in gauge table

- POS 3000 3D graphic control

- Tool positioning display alongside the clamping beam

- Production status indicator lights

Published in:

blechnet 03/2019