Schröder Group at EuroBLECH 2018

Trade fair premiere for the advanced fully-automatic sheet metal handling system

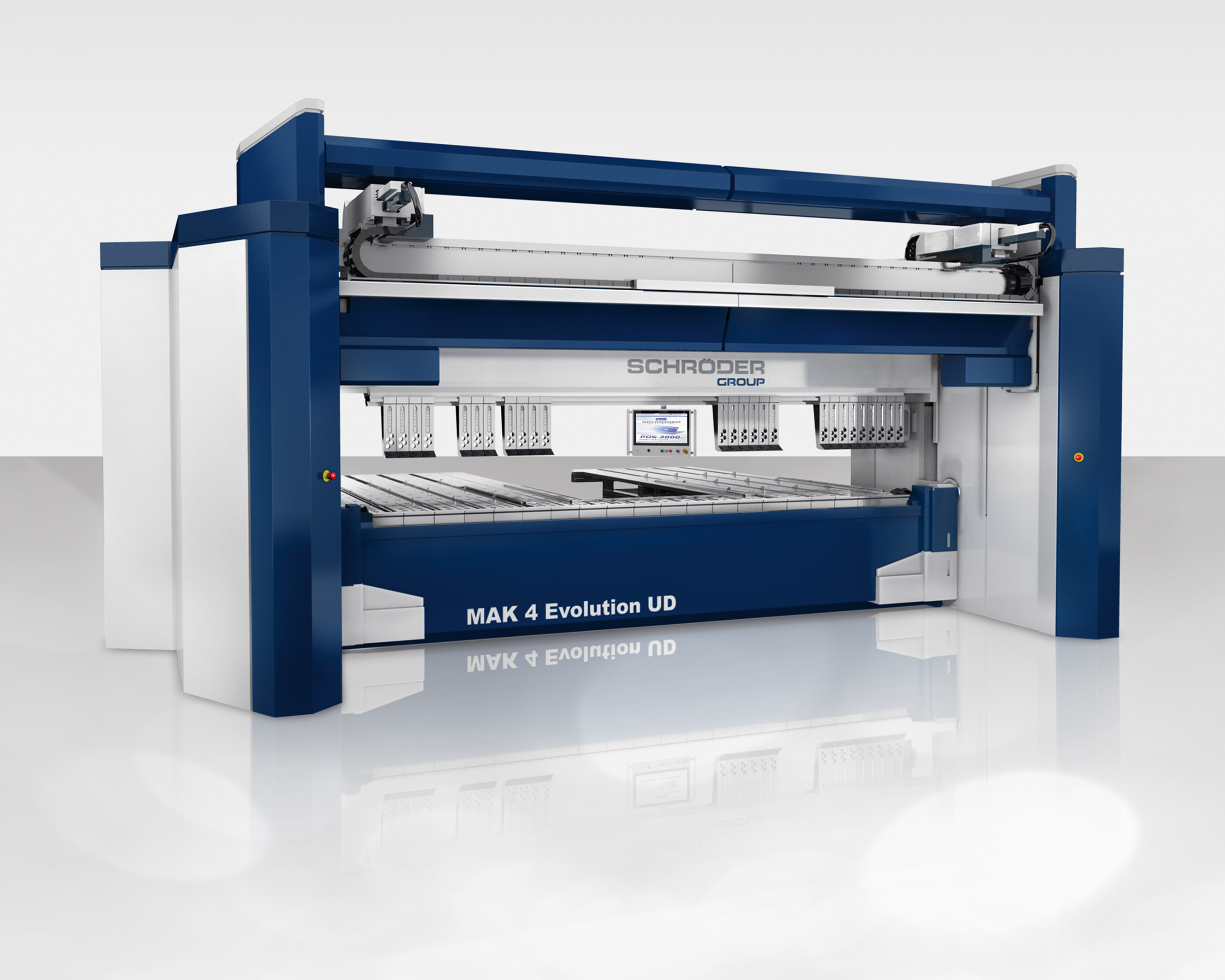

Wessobrunn-Forst (Germany), 29 August 2018 – Hans Schröder Maschinenbau GmbH and SCHRÖDER-FASTI Technologie GmbH are showing their extensive range of sheet metal working machines in hall 11 booth A48 at this year’s EuroBlech in Hanover: from shears, slip bending rolls, flanging machines up to powerful folding machines for the sophisticated handicraft business and the industrial sector. Exhibition highlight will be the innovative Schröder Advanced Handling System (AHS) that will be shown for the first time in public. This novelty can be seen on the motorized folding machine MAK 4 Evolution UD with a working length of 4000 mm and sheet thickness up to 5.0 mm.

The Advanced Handling System developed by Schröder Group achieves a high level of automation when folding sheet metal. Before, this was only possible with the additional use of handling robots. Thanks to the combination of Up-and-Down-folding beam, suction gauge and the advanced handling system the software control POS 3000 enables a fully automatic procedure of the whole bending program without any manual intervention. Additionally. the MAK 4 Evolution UD on which the AHS will be shown is equipped with a fully automatic tool changer. Thus, you can achieve unparalleled automation, efficiency and repeat accuracy during industrial bending both in serial production, small production or for single pieces.

Extensive portfolio for sheet metal processing

Schröder Group is showing trade fair visitors efficient semi-automation on the SPB Evolution UD with tool changer, a PowerBend Industrial UD for up to 6 mm thick sheets as well as on the PowerBend Professional UD that is very popular in bigger handicraft workshops. Thanks to its optionally available suction gauge all bends for one side of the sheet can be done automatically step-by-step after gauging the sheet against the folding beam. One more interesting detail of the PowerBend Professional: The rotating clamping beam makes available a second set of tools in no time.

The hydraulic shear PowerShear Professional 3,000/6.0 with an energy-efficient drive is exhibited with a pneumatic sheet support and a frequency-controlled motorized back gauge of 10 – 1000 mm. A further shear that will be shown is the PDC NC 3,200/3.0. Popular machines from the portfolio of SCHRÖDER-FASTI on the booth are the 134-15/2.0 slip bending roll and the 416-63/1.5 flaring machine.

As an example for a manual folding machine Schröder Group presents the versatile folder ASK 3 1,250/1.0. Thanks to its segmented tools on all beams it enables large clearances for complex work pieces.