PowerBend Universal

Details

- Software control

- Positioning control Classic Bend 10,1″ screen on swivelling arm

- Radius function

- Clamping beam

- Clamping beam stroke 350 mm (325 mm with manual clamping device)

- Clamping beam geometry 48°

- Middle motor clamping beam drive: 3.0 kW (controlled through contactors, 20 mm/sec, trapezoidal spindle)

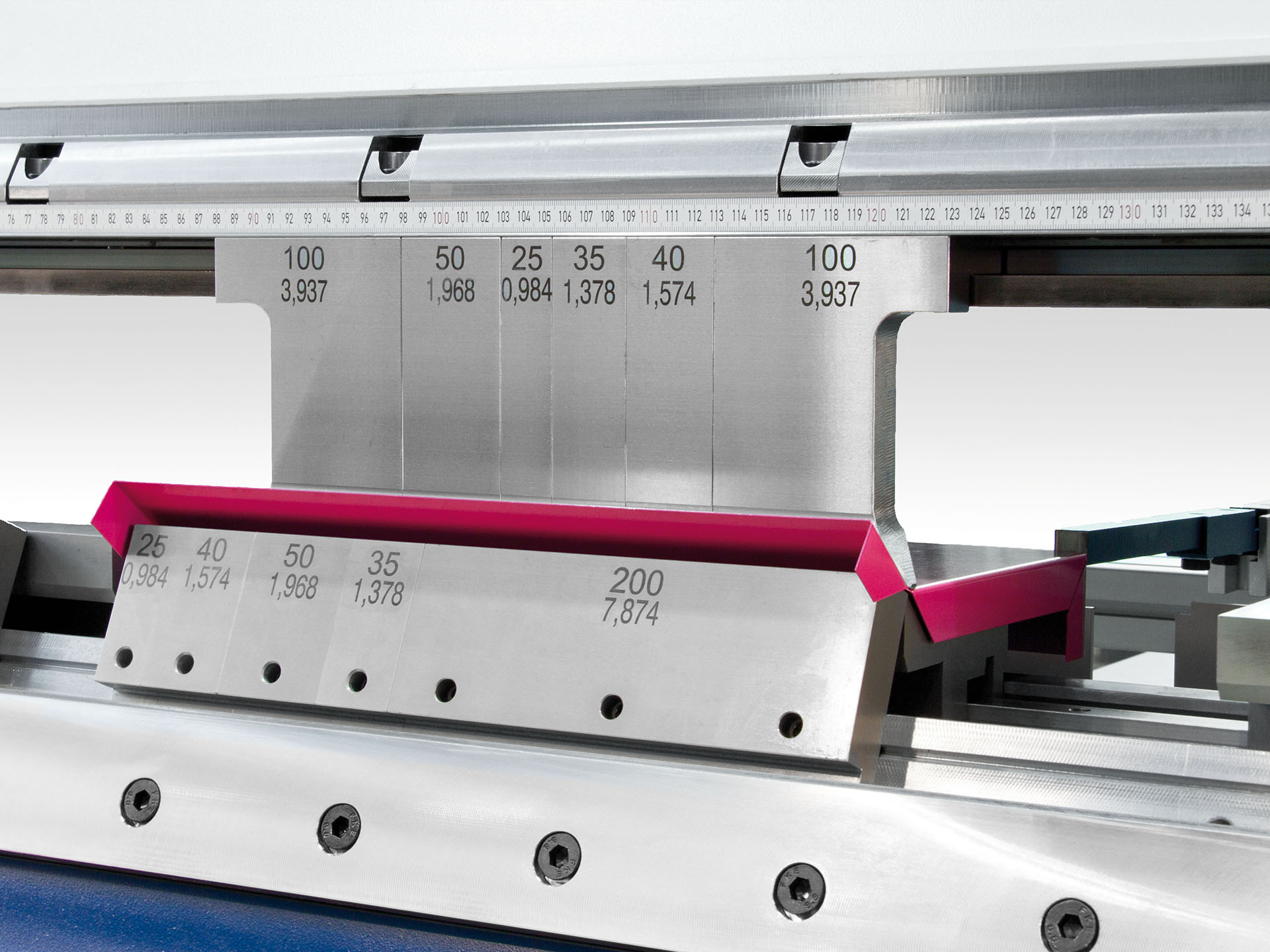

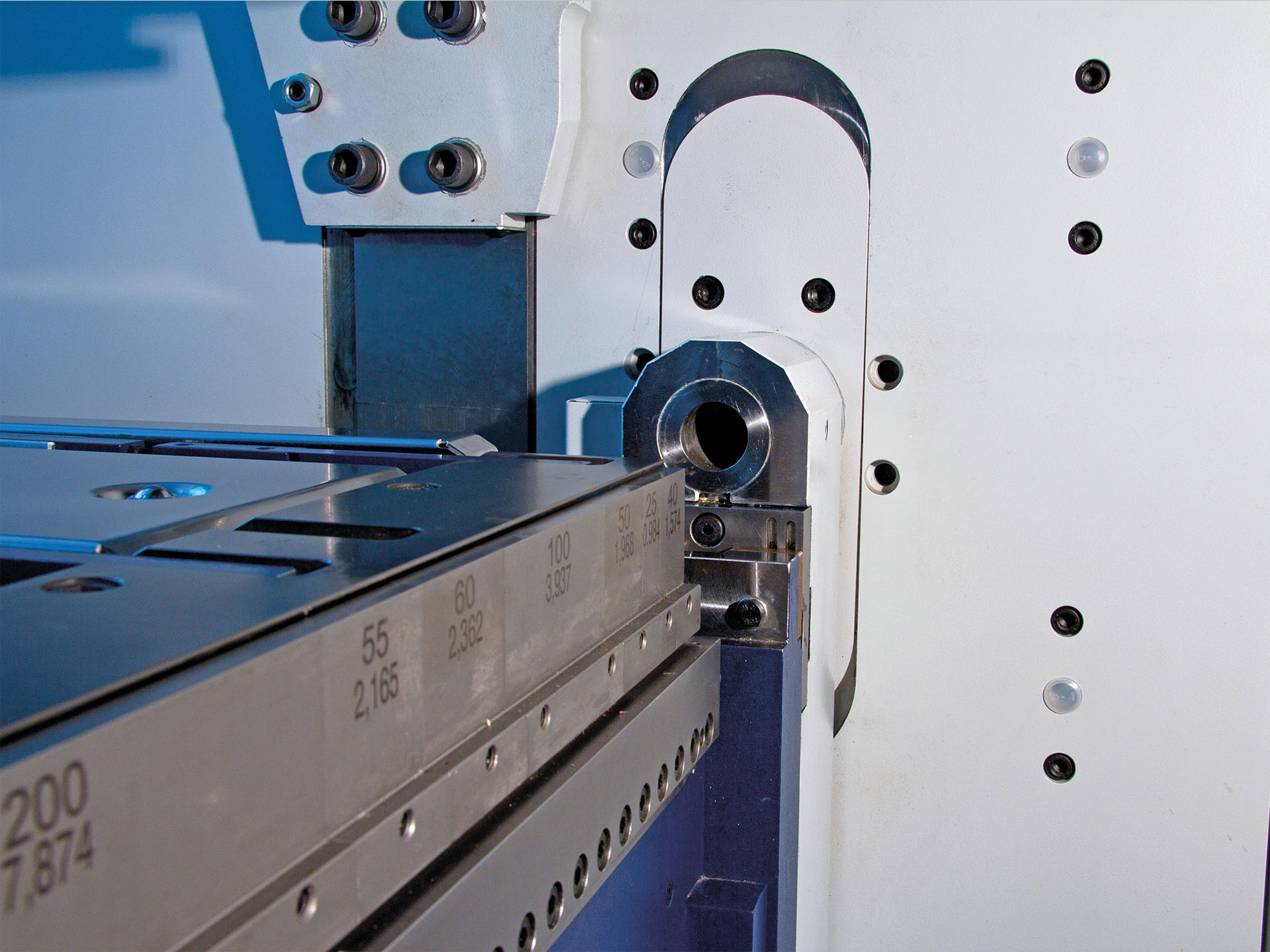

- Manual tool clamping device for clamping beam

- Folding beam

- Drive: 2 × 2.2 kW (converter-controlled, 85°/sec)

- Manual folding beam adjustment 80 mm

- Manual tool clamping device for folding beam

- Bottom beam blade, ca. 1100 N/mm², one piece (minimum gauge 10 mm)

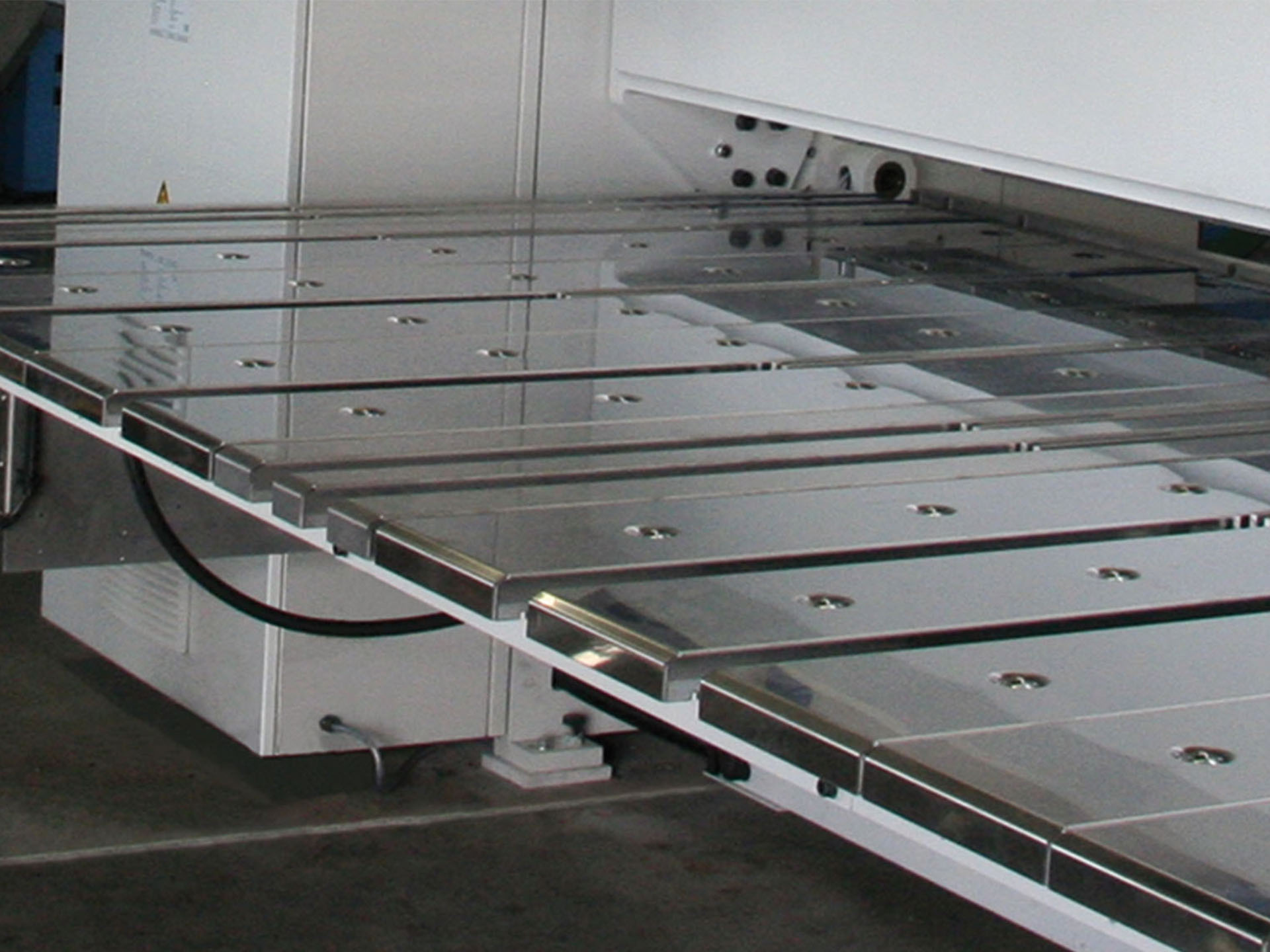

- Back gauge

- Motorized back gauge up to 1000 mm, pneumatic pop up gauge fingers, sheet support table with balls, recirculated ball screws

- Work safety

- RFID switch for securing the cabinet doors

- Foot switch

- Others

- Anchor plates incl. dowels

- Standard machine without folding- and clamping beam tools

Technical Data

| Model | Working length | Sheet thickness 400 N/mm2 | Machine length | Machine width | Machine height |

| [mm] | [mm] | [mm] | [mm] | [mm] | |

| 2,000×4.0 | 2,040 | 4.0 | 3,814 | 1,694 | 1,510 |

| 3,200×3.0 | 3,240 | 3.0 | 5,014 | 1,694 | 1,510 |

| 4,000×2.5 | 4,040 | 2.5 | 5,814 | 1,694 | 1,510 |

| Clamping beam | ||||

| Model | Geometry | Stroke | Drive power | Speed |

| [°] | [mm] | [kW] | [mm/s] | |

| 2,000×4.0 | 48 (180) | 350 | 3/5.5 | 20 (46) |

| 3,200×3.0 | 48 (180) | 350 | 3/5.5 | 20(46) |

| 4,000×2.5 | 48 (180) | 350 | 3/5.5 | 20(46) |

| Folding beam | |||||

| Model | Drive Power | Speed | Folding beam adjustment | ||

| [kW] | [°/s] | [mm] | |||

| 2,000×4.0 | 2 x 2.2 | 66 | 80 | ||

| 3,200×3.0 | 2 x 2.2 | 66 | 80 | ||

| 4,000×2.5 | 2 x 2.2 | 66 | 80 | ||

Software

POS 2000 Professional

the standard for industrial folding machines

The proven POS 2000 Professional makes programming a folding machine fast

and comfortable. The desired program components can be selected from a

comprehensive and expandable catalog, the angle and side dimensions are easily

changed by pressing the monitor.

The control software displays exactly what the machine is doing: The

folding machine, work piece, and tool are displayed schematically and updated

for every bending step. Anyone who programs preparation of the work away from the

machine can test the quality of their program using the bending simulation,

which effectively avoids waste and delays during production.

The software not only controls the machine, but also offers assistance to the user:

all of the necessary operator activities like turning, rotating, etc. are

displayed for each bending step.

ClassicBend

the new clearly laid-out alphanumeric control

With Classic Bend, we have developed a modern alphanumeric control system – self-explanatory and very easy to program.

Classic Bend controls the clamping beam and folding beam with a travel measuring system and also the motorized back gauge via digitally controlled frequency converters.

The user interface is practice-oriented and clearly laid out. The display combines easy-to-read symbols with text and numerical displays.

Do you want uniform folding programs for sheets of different quality? You can enter corrections to the settings for the clamping beam and folding beam for each bend.

With Classic Bend, Hans Schröder Maschinenbau is setting new standards in the control of folding machines for trade and industrial small series production.

Werkzeuge/Optionen

Options

- Clamping beam

- Clamping beam geometry 180°

- Hydraulic tool clamping

- Folding beam

- Power-Package folding beam increases the bending capacity by 1 mm: reinforced drive incl. folding blade 35 mm (1100 N/mm²) requires converter package (65°/sec)

- Central crowning device, manual

- Motorized folding beam adjustment 80 mm

- Central crowning device motorized, requirement: POS 2000 Professional and motorized folding beam adjustment

- Clamping device, pneumatic (only in combination with WZS 15100 and crowning device)

- Technology package POS 2000 Professional

- Technology package nanoTouch

- Table and back gauge

- Motorized back gauge up to 1600 mm, closed, 2 sectors with pneumatic lowering device, sheet support table with balls, recirculated ball screws (+/- 0,1)

- Back gauge extension to J- or U-gauge possible: Basis: motorized gauge up to 1600 mm, closed

- 2 fixed square arms (left and right)

- 2 pneumatic pop up square arms (only in connection with POS 2000 Professional)

- Software control

- POS 2000 Professional PC Version (external programming), 1st licence

- POS 2000 Professional PC Version

- Safety and others

- Additional equipment for 2-man operation control in accordance with accident prevention rules required

- Tool cart for blades and segmented tools

- Operation from the rear in addition, 2nd footswitch, access security in front via light barriers, horizontal light curtain aisle side

- Foot switch on rail for lateral movement

- Voltage tranformer 12 kVA

- Air conditioner

- Various bottom beam-, folding beam-, and clamping beam tools