Hans Schröder Maschinenbau presents the motorized folding machine EVO-CENTER

Fully-automatic sheet metal folding

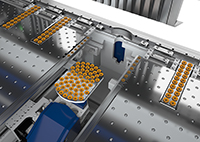

Wessobrunn-Forst (Germany), 5 November 2019 – Hans Schröder Maschinenbau GmbH presents the latest innovation of the industrial high-performance Evolution-series. With a working length of 4,040 mm the EVO-CENTER bends up to 3.0 mm thick steel sheet. The 3D-graphic control POS 3000 operated via a 22“ Touchscreen, controls the almost automated production. With its innovative Advanced Handling System (AHS) incl. a rotating plate and an automatic tool changer this machine can be extended perfectly to a fully automated bending center of a production line.

The EVO-CENTER is made for series production with utmost repeat accuracy, and due to a very fast tool changer it is also perfect for the flexible production of single pieces and small series. With the POS 3000 3D graphic control developed inhouse you can not only open ready bending programs but you can also do a quick and comfortable programming directly at the machine.

Automatic tool change in less than one minute

The software control mounted on a swiveling arm with a 22“ TFT-Touchscreen control shows the product and the machine in a three-dimensional visualization. All adjustments such as the folding beam- and the folding center adjustment as well as the crowning system are motorized. The change of up to 400 mm high tools on the clamping beam with hydraulic tool clamping is managed by an automatic tool changer with two asynchronously movable grippers. The tool changer is very fast: Tools can be changed at any height easily from the magazines that are positioned on the left and right side of the machine – no setup takes longer than one minute.

This machine is perfect for the use of big sheet metal plates and sensitive surfaces: The sheet gets aligned once with the reference gauge fingers, the suction cups fix the sheet and the machine does the rest of the sheet metal processing on its own. Thanks to an Up-and-Down folding beam and a rotating plate with suction cups all sides of the workpiece can be bend without any further interference by the operator.

Easy handling of heavy sheets

Two independently movable gauge tables with steel balls and the suction gauge facilitate the handling of big sheet metal formats up to 3,700 × 1,500 mm. Furthermore also small workpieces can be produced on the EVO-CENTER: Thanks to a choice of four differently sized suction plates sheets up to 250 mm x 300 mm can be processed automatically. If the EVO-CENTER is planned to be integrated into a fully-automatic production line, the software team of Schröder Group integrates the control of manipulators, conveyer systems or robots into the software control POS 3000.