Schröder Group at Blechexpo 2025

High degree of automation and easy operation

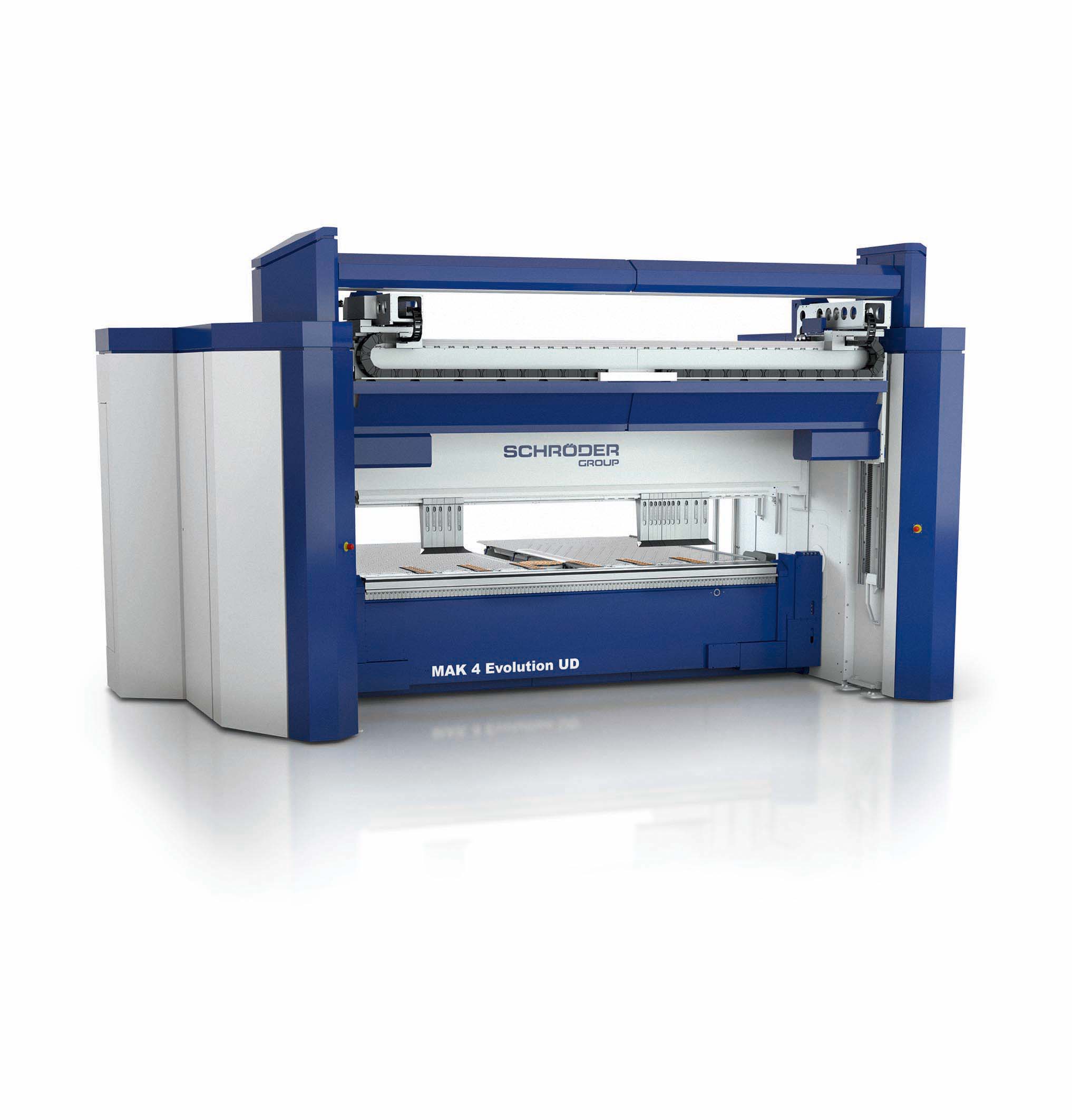

Wessobrunn-Forst (Germany), 5 August 2025 – The Schröder Group is once again demonstrating its leading role as a manufacturer of sheet metal processing machines at the 17th Blechexpo. From October 21 to 24, 2025, the company will be exhibiting sheet metal working machines for the most demanding requirements at booth 1804 in hall 1 of the Stuttgart Exhibition Center. The highlight is the MAK 4 Evolution UD for fully automatic folding of up to 6 mm thick sheet metal.

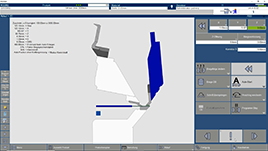

The MAK 4 Evolution UD will be on show at Blechexpo in a version with a working length of 3200 mm, fully equipped with automatic tool changers for the clamping beam and folding beam, which significantly reduce set-up times. With the POS 3000 3D graphic control, the up-and-down folding beam, and the Advanced Handling System (AHS), workpieces can be completed fully automatically after one single positioning of the sheet metal. The AHS is a pneumatic rotating plate with suction cups. It can safely and precisely position blank sheets up to 3700 × 1500 mm in size and weighing up to 236 kg. The AHS includes a camera system for measuring the sheet metal contour, motorized reference axes for setting, and its own safety concept.

Ingenious feature

The PowerBend Multi (PBM) 4000 × 2.0 mm motorized folding machine is an exhibition machine that sheet metal workers will love for three special features, among others: The back gauge can be set at an angle to enable tapered bending. This means that profiles can be manufactured that fit precisely into one another. The motorized folding beam adjustment of the PBM enables quick changes between different sheet thicknesses without manual intervention. And the rotating clamping beam not only offers flexibility, but also the extremely practical hemming function: Hemmed folds can be produced completely in one step with the folding beam instead of in two steps with the clamping beam, as was previously the case. This hemming function is now also available on another machine on display at the tradeshow: the PowerBend Professional. This function enables hemmed folds to be produced industrially in series with maximum repeat accuracy.

Folding, cutting, slip bending

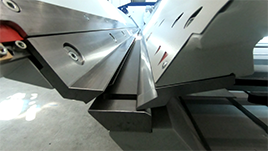

Another powerful folding machine is the PowerBend Industrial UD 4000 × 5.0 mm. It is the perfect solution for industrial processing of thick and thin, large-area sheets. Its biggest advantage is the clamping beam stroke of 850 mm, which allows box depths of up to 400 mm. Thanks to the motorized folding beam movement, switching between positive and negative bends with the up-and-down folding beam is particularly fast and precise.

The Schröder booth will cover topics of cutting with the PDC 3200 × 3.0 mm motorized guillotine shear. The motorized blade gap adjustment eliminates the need for time-consuming manual adjustment and operating errors, as the position is automatically calculated by the software control. Thanks to the blade gap adjustment of 0.02 mm, the PDC cuts thin sheet metal with almost no burrs.

With the 134/15/2 mm motorized slip bending roll, Schöder-Fasti demonstrates what it is famous for: machines for rounding with maximum repeat accuracy and the highest precision. The repeat accuracy in the feed and height adjustment of the rear roller is ±0.1 mm. With the CR80 control system, not only can several radii be run in succession, but a so-called path curve-controlled run can also be programmed. This prevents stops and thus unsightly creases in the sheet metal.