Schröder Group makes automation an option

Gauge once, bend automatically

Wessobrunn-Forst (Germany), 29 July 2025 – The Schröder Group has made its Advanced Handling System (AHS) an optional feature of the EVO Center and MAK 4 Evolution UD folding machines. The innovative system had previously been revised in order to demonstrate maximum precision even in continuous operation with heavy sheets. AHS can be integrated into more advanced automation solutions with robot loading and unloading, which Schröder offers together with Starmatik.

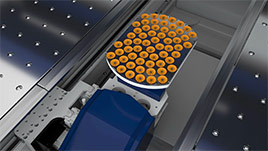

AHS was previously only available as a customer-specific option for the MAK 4 Evolution UD. The back gauge technology with a suction plate turntable has been revised for even more reliable processes and shorter cycle times. The optimized rotating plate kinematics allow for more precise positioning, even with heavier workpieces weighing up to 236 kg. The more stable mechanics and control system are designed for continuous operation and the rotating plate can be scaled for different component sizes. The smallest sheet format that the AHS can handle measures 360 × 360 mm, the largest 3700 × 1500 mm. The AHS includes a camera system for measuring the sheet contour, motorized referencing axes for positioning and an additional operating terminal on a rotating and height-adjustable column. The automatic system of course comes with its own safety concept.

How AHS works

AHS requires an Up-and-Down folding beam. The sheet is attached once to the referencing axis. The rotating plate with suction cups fixes the sheet and now positions it for the up and down bends on the previously attached side. The sheet is then automatically aligned with the rotating plate for the bends on the next side. The system represents the highest degree of automation that can be achieved without the use of robots and is ideal for unmanned shifts.

Additional gauge option: Gripper

Another gauge option is now available for the EVO Center and MAK 4 Evolution UD: the gripper gauge. This was previously a feature of the EVO Heavy Duty, a folding machine that bends up to 16 mm thick steel sheets. The gripper gauge is always useful when the suction plate gauge does not work. This is the case with perforated sheets or when a long flange to be bent creates a leverage effect with very heavy sheets.