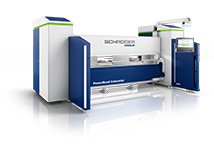

PowerBend Industrial revised by Schröder

Folding up to 6 mm thick steel sheet

Wessobrunn-Forst (Germany), 18 June 2025 – The Schröder Group has redesigned its popular PowerBend Industrial and made it even more robust and faster with a new bending beam and a more efficient drive system. The opening height of the clamping beam has been increased to 850 mm and tools up to 400 mm high can now be used. The PowerBend Industrial is available in two versions: with a working length of 4000 mm for up to 5 mm thick sheet steel and the 3200 mm version, which bends 6 mm sheet steel. The Schröder Group originally closed the gap between its high-end folding machines and thin sheet metal machines with the introduction of the PowerBend Industrial in 2016.

The new folding beam is characterised by an even more rigid design with improved force distribution, which increases precision. Optimised kinematics, for example when changing from positive to negative bends, ensure shorter cycle times and improved folding quality – even with complex geometries. The set-up times for changing folding beam tools have also been significantly reduced thanks to a quick-change system.

New drive system

The PowerBend Industrial has been equipped with more energy-efficient servo drives with higher dynamics. In some areas, the engineers have found ways to use components with less wear, which will reduce maintenance costs in the long term. Intelligent production feedback was also introduced, which will be used in automation and digitalisation projects in line with Industry 4.0.

„We expect the redesign of the PowerBend Industrial to significantly increase productivity, especially for medium to high quantities,“ says Thomas Ostermair, Head of Sales at Schröder Group. „We also see improved folding quality for demanding materials such as stainless steel and high-strength sheet metal. Ultimately, efficiency and ease of maintenance will reduce operating costs for users.“

Popula features

The number of manual interventions is minimised with the now standard up-and-down folding beam and the optional suction plate stop as an extension of the back gauge. The combination of both technologies allows the sheet metal to be positioned on the horizontally aligned bending beam and fixed with the suction plate back gauge. The suction plate back gauge then positions the sheet for all bends on the applied side – thanks to the up-and-down folding beam with bending and counter-bending and without further intervention by the machine operator. Functions such as radius folding for step-by-step, precise folding of radii and hydraulic clamping of the clamping beam with LED tool position indicator for quick tool changes further expand the application options. If required, sheets can also be positioned from the front. A processing option that is used in many manufacturing companies for narrow sheets and profiles. To make this highly efficient application option even more convenient in practice, the PowerBend Industrial is equipped with a touchscreen on the swivelling arm.

The PowerBend Industrial will be exhibited at Blechexpo at Stand 1804 in Hall 1 in the version with a working length of 4000 mm x 5.0 mm.