Schröder Group at Dach+Holz International 2026

Efficiency-enhancing solutions for the roofing industry

Wessobrunn-Forst (Germany), 17 December 2025 – When the doors of Dach+Holz International open in Cologne from February 24 to 27, 2026, the Schröder Group will once again be represented with pioneering technologies for sheet metal processing. In Hall 8, Booth 8.326, the machine manufacturer will showcase its broad portfolio, ranging from proven manual machines to high-precision motorized folding machines. The focus will be on how efficiency, repeat accuracy, and flexibility in the sheet metal industry can be further increased.

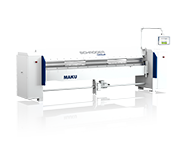

The two motorized folding machines on display, MAKU and PowerBend Multi, showcase an innovation from Hans Schröder Maschinenbau that makes work significantly easier for roofing workers: tapered bending. An electronically controlled, two-axis backgauge with an accuracy in the tenth of a millimeter range allows tapered and pluggable profiles to be bent. This makes it possible to effortlessly and precisely reproduce, for example, parapet or wall copings and roof edge finishes or cladding with a slope in the workshop, which previously had to be done manually on site. The MAKU is the versatile basic machine for folding up to 2.0 mm thick sheets. A new version will be on display at Dach+Holz, which allows for significantly faster clamping of the sheets.

Innovative way of folding hems

The PowerBend Multi (PBM) folds up to 2.5 mm thin sheets. Schröder demonstrates another innovation with this machine. It has a rotating clamping beam that allows you to switch to a different geometry or tool station. This clamping beam also enables a patented process for folding hems. It is reset and the sheet metal is clamped so that the folding beam has space beyond the vertical. In this way, folding hems can be bent and pressed in a single operation – precisely and in a time-saving manner. The model on display at the exhibition demonstrates this on a 2 mm thick steel sheet with a length of 3200 mm.

A classic craft machine

With the AK (2000 × 1.5 mm) and the ASK 3 (1250 × 1.5 mm), Schröder presents two tried-and-tested machines for the roofing industry. The AK has a foot lever mechanism and optional equipment such as a manual backgauge with digital display, folding angle stop, and a pneumatic folding aid. The ASK 3 segment folding machine offers maximum flexibility for a wide variety of workpiece shapes with its patented eccentric quick-clamping system and large clearance heights of up to 180 mm for the clamping beam, 120 mm for the bottom beam, and 142 mm for the folding beam.

Motorized shear with control option

In addition to folding machines, the Schröder Group is also exhibiting a motori-zed shear. Although the MHSU is the entry-level model among motorized shears, it is very convenient and precise thanks to its 750 mm backgauge, which can be adjusted from the front and features a digital display. The machine on display at the exhibition shows what is possible with optional extras. It is equip-ped with an NC positioning gauge that allows different gauge lengths to be pro-grammed. The variable sheet metal hold-up device also allows the user to spe-cify at the touch of a button whether the sheet metal being cut is ejected for-wards or backwards.