Precision in the service of sustainability

Schröder folding machine PowerBend Professional at HB Hamburger Blechwerk mbH

Customer

Hamburger Blechwerk is a qualified, certified specialist company and manufactures sustainable metal roof edge and facade profiles. The company has developed a system for creating solutions that are both visually sophisticated and ecologically sound. For this purpose, natural insulation materials and steel sheet cladding are used, which are characterized by an environmetally friendly coating. The easy-to-process sheets protect buildings for many decades and then one hundred percent recyclabe https://www.be-bauwerkssanierung.de/.

Success

Wieslaw Szczerba developed a panel system consisting of a few standard modules for wall and parapet cladding, which can be adapted to the different areas of application and combined with each other in just a few steps. The patented modular system offers the only flangeable press-on rails with decking profiles. And because it consists of sheets only 0.6. to 0.7 mm thick, it can be cut and folded by hand on the scaffolding. For this purpose Szczerba has invented and edging plate that allows various head and corner edgings on the prefabricated panels and profiles. The system offers enourmous savings in resources and time.

A challenge for the machine builders.

„Customers today are very demanding and used to perfect design. They want a roof like an iPhone design with Mercedes quality,“ says Szczerba. Indeed, his small-scale cassette system offers a refined look with clean surfaces, lines and invisible fastening. And this is precisely where the difficulty lies. The edges and spacing must be absolutely uniform. The panels are therefore machined to an accuracy of a thenth of a millimeter. An extreme requirement, as became apparent when Szerba went in search of a folding machine in 2017. “Only Schröder was accurate enough and at the same time had sufficiently robust crowning,” says the managing director of the Hamburg sheet metal plant, summing up his search for a machine. The choice fell on the Schröder PowerBend Professional UD with 4040 mm working length. Hamburger Blechwerk ordered special tools and another unique machine option: the rotating clamping beam. It offers the possibility of providing a second tool setup in the blink of an eye, so to speak.

Opens up horizons.

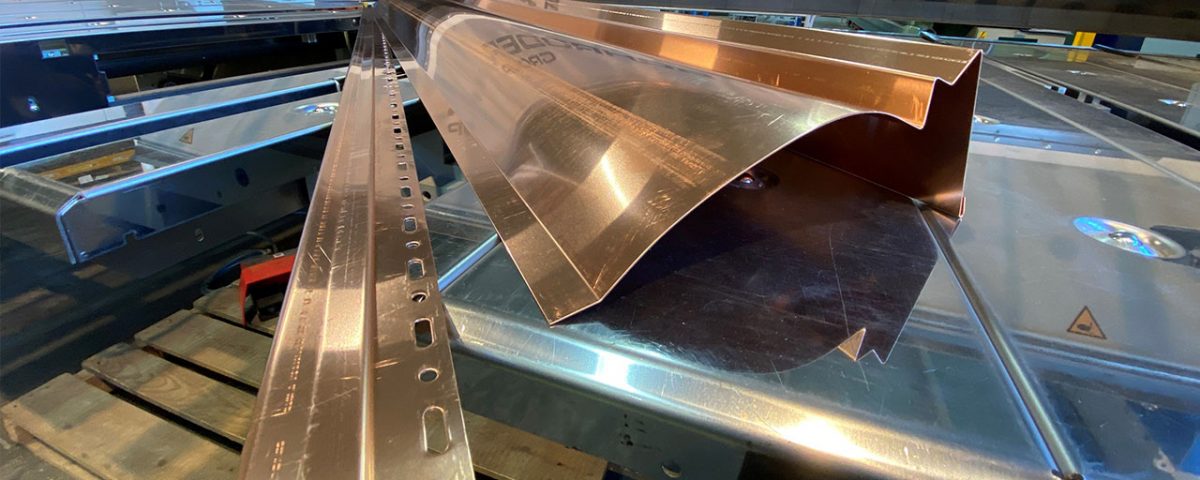

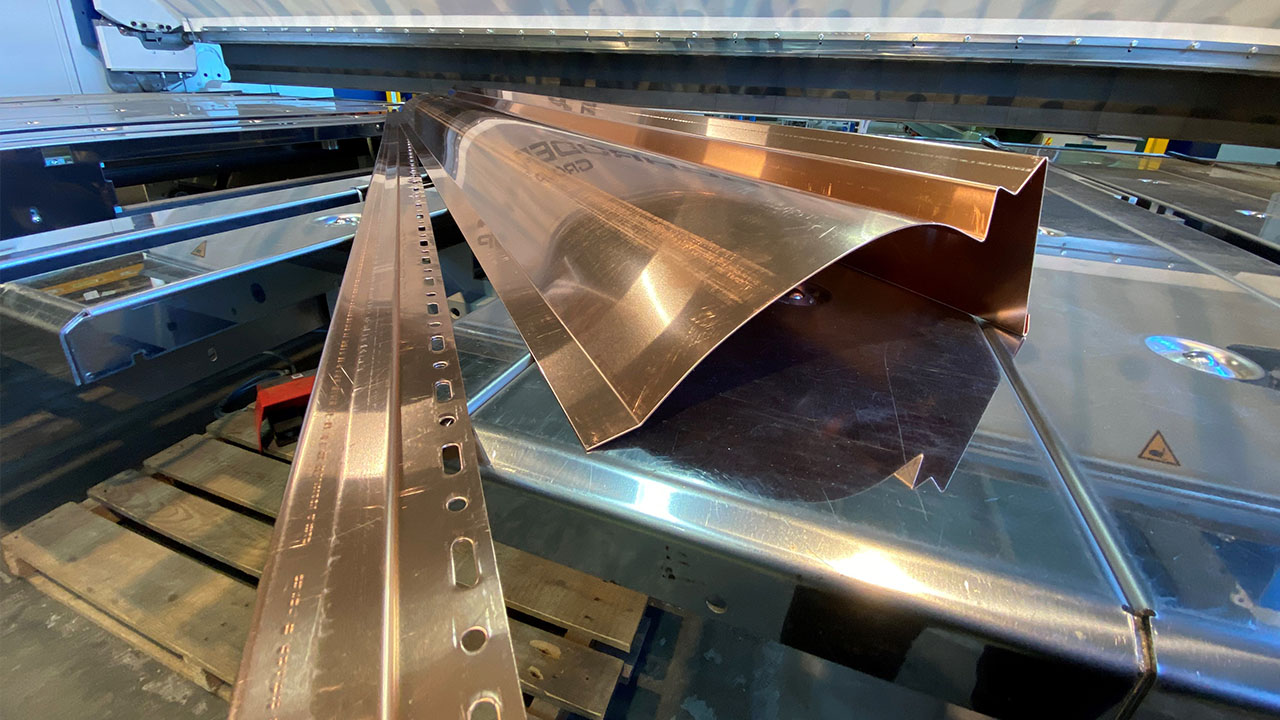

After the Schröder machine was purchased at the end of 2017, it was initially located in Blechwerk 1 in Hamburg-Stellingen. However, the space was no longer sufficient, and shortly thereafter it moved together with several profiling machines to the new Blechwerk 2 hall in the municipality of Rellingen in the district of Pinneberg, which is adjacent to Hamburg. With its exemplary repeatability, the new machine had made series production of the cassette/quick panel system and the filigree press-on rails possible in the first place, but beyond that Szczerba notes, “The PowerBend opened up the horizon for us to develop new minimalist systems so that we can also clad larger facades with our unrivaled cassette system.” The machine also offers additional possibilities in other areas. For example, copper gutters for listed buildings are created using radius-step bending. In this process, sheet metal is pressed with the clamping beam against an angle formed by the bottom beam and folding beam – a slight curve is created. This is now repeated as often as required in steps of any fineness. The result is a perfectly rounded sheet that shows nothing of its step-by-step forming.

Outlook.

The PowerBend Professional UD is of central importance in the machine park of the Hamburg sheet metal plant and for the further development of its material-saving panel system. The size of the machine still leaves room for improvement in terms of solutions with larger panels. Szczerba is also currently developing an answer to the question of how to realize large stable surfaces with the thinnest of sheets: a composite material – but not a non-recyclable plastic solution – but a completely fusible steel-on-steel solution: thin sheet bonded with corrugated sheet. One can be curious.

Machine in operation

PowerBend Professional

- Folding machine up to 2.5 mm sheet thickness

- Working length 4,000 mm

- Graphic control POS 2000 Professional

- Clamping beam stroke 350 mm

- Rotating clamping beam

- Radius function

- Remote maintenance